|

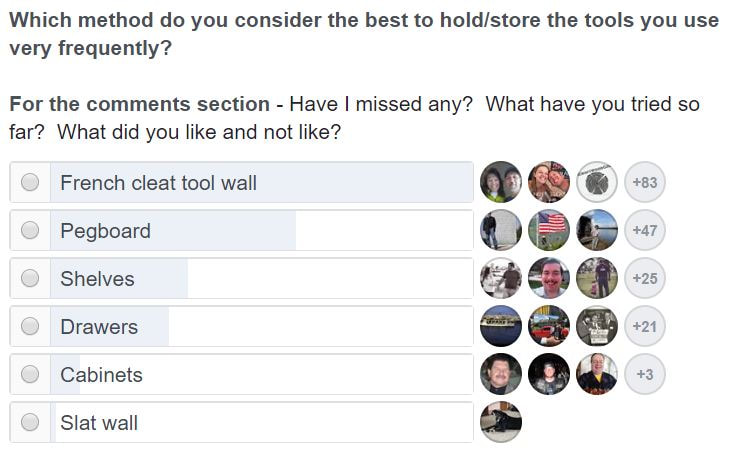

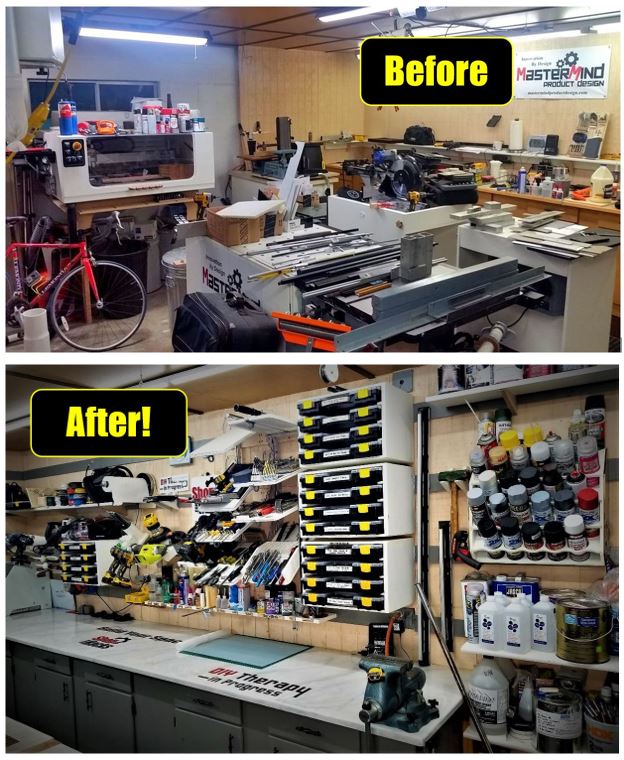

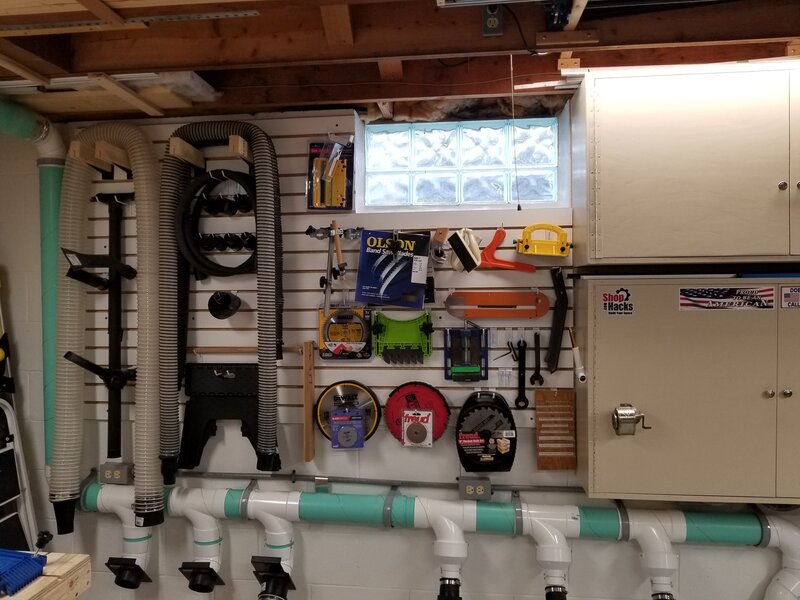

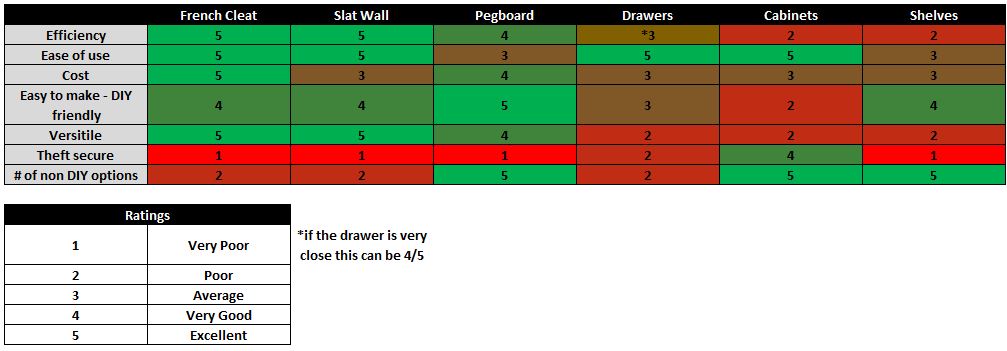

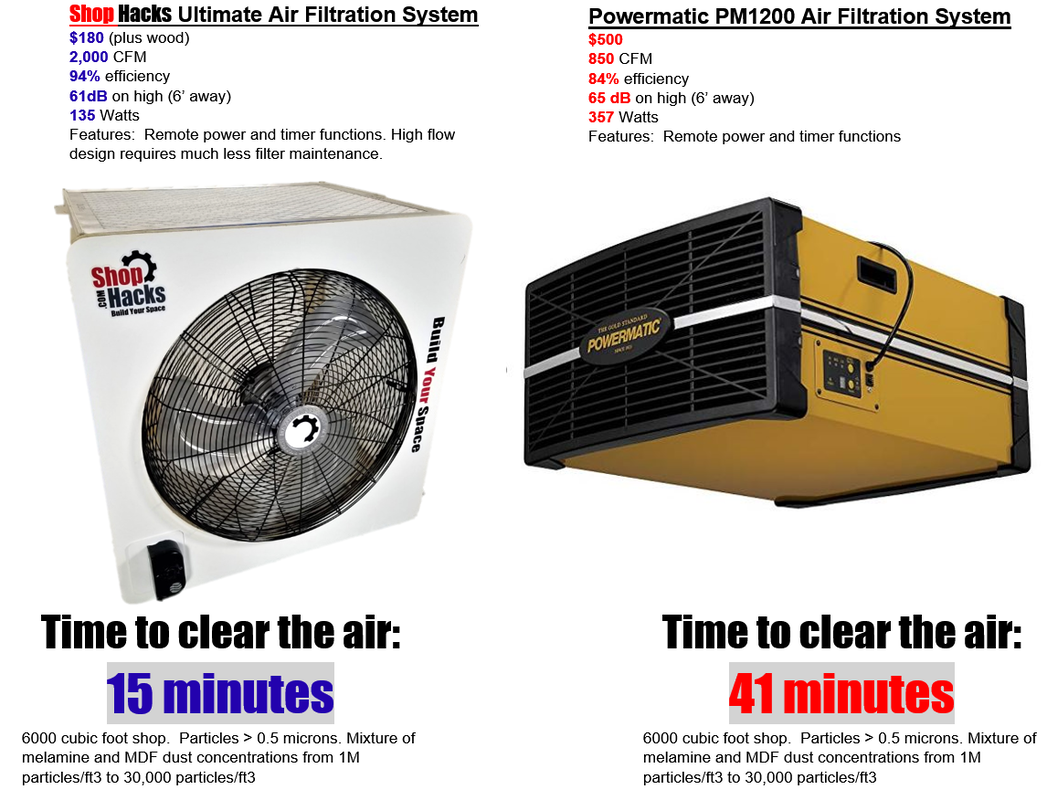

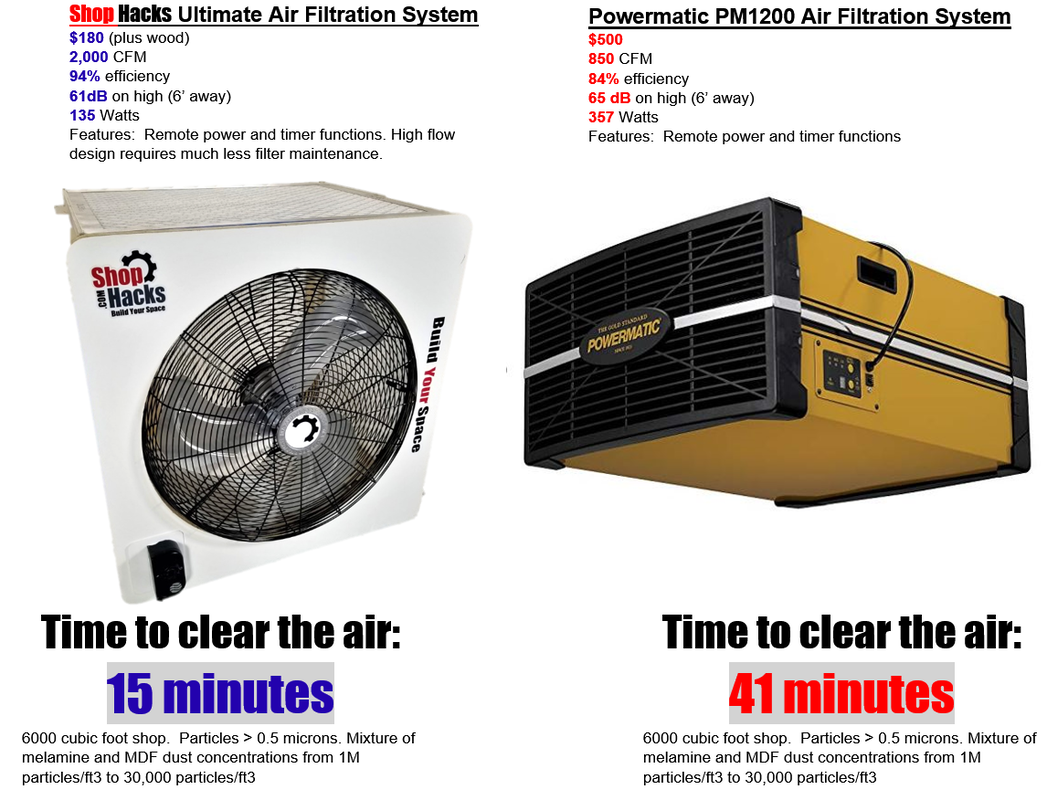

If you would like to receive FREE Shop Hacks like this every Friday at 3:30 Eastern Time... subscribe below... What are your Tool Organizer Options and what might work best in your shop? There are 6 popular types of tool organizers... 7 if you count the pile of tools on your workbench ;-) The following poll was taken in the Shop Hacks Facebook group regarding which system you like the best... I was a little surprised about how much French cleats came out ahead of the rest of the options combined, but I understand why. I'll start with some pictures of each of the popular DIY options then we will get into which ones work best for different situations. At the end of the article I'll show you some of the systems available that you can purchase ready-made. Note... Don't miss next week's article because I will introduce a new organization product that you can use to Build YOUR Space! I'm excited to unveil this innovative but simple and inexpensive Shop Hacks system to all of you! I've improved on an already great system and I'll offer it in a package that takes the hassle out of organizing your workshop! Stay tuned... French Cleats - everything on my tool wall is hanging on a french cleat. I like them because they make it very easy to evolve my tool wall as my workflow and needs change. It is also cheaper and more versatile than any other system. French cleats are really the most versatile option because you can still use all of the other options on a French cleat wall. You can hang cabinets or drawer modules, shelves or even sections of pegboard is you want to. Pictures of Shop Hacks Facebook Group members French Cleat Setups Pegboard is the next most popular option. That's understandable since pegboard is readily available, is relatively cheap, has a wide variety of accessories available and has been around since our grandfathers were working in their shops. The photos below were submitted by members of the Shop Hacks Facebook group. Particularly interesting is Mike Gallucci's blue powder coated metal pegboard workbench design. Great job Mike and thanks for sharing your innovative creations with the group! Slat Walls show up from time to time and they are just as versatile as French cleat walls but they are not nearly as popular for some reason. I believe they are more popular in Europe than in the US. There are a number of very nice accessories available for slat walls. Shelves, Drawers, and Cabinets - I would venture to guess that 99% of us use some combination of these three in our shops. They are ubiquitous and readily available at any big box store in both ready-made and DIY options. They are the default choice if you don't want to spend your energy trying to make your shop as efficient as it can be. However they are horribly inefficient compared to open tool storage and tend to become dumping grounds and hoarding areas where tools and materials go to die. The Shop Hacks Philosophy - Never put frequently used tools or materials in a drawer or cabinet or on a shelf. Use open tool storage within arms reach of each of your work areas and you will spend much less time walking, sorting, opening, closing and moving things around and more time making, fixing and building. For more about how to organize your tools without feeling overwhelmed, check out these articles... tool-organization-how-to-organize-your-tools-without-feeling-overwhelmed.html workshop-organization-how-to-organize-your-materials-and-hardware-without-feeling-overwhelmed.html I ran a quick time study the other day to see how much time I saved by locating my frequently used tools within arms reach compared to where I used to store them - in a toolbox. It took me 3 seconds to grab a tool, touch the counter and put it back using my french cleat tool holder located next to my main work area. It took me 30 seconds to walk to the toolbox, open the drawer, find the tool and grab it, close the drawer, walk back then repeat the process to put the tool back. I'll let you do the math but I estimate that I buy back between 40 and 80 hours of project time EACH YEAR by having my tools in the open and within arms reach. You can organize all of your frequently used tools and materials in less than 80 hours of work so, IMO, it is a no-brainier to use open tool storage. One caveat... Open tool storage requires you to work on your dust collection first. Without effective dust collection and air filtration you will always have a film of dust on everything that is out in the open. The Shop Hacks Ultimate Air Filtration System will take care of most of the fine dust that settles on your tools after your work session is over but not everything. In future articles I'll show you how to achieve near 100% efficient dust collection on all of your tools (under 2 hp) with just a cheap shop vac. I've proved my methods using laser particle counter testing. Advantages and Disadvantages of Each System The following table is my subjective analysis of each system but think about it and decide for yourself if you think using open tool storage is worth the time it will save you over the years. Keep in mind that French cleat and slat walls may be used with all of the other systems which makes them universally compatible. I.E. you can hang cabinets, drawers and shelves using French cleats or slats. How to Build A French Cleat Wall I'll go into this in more detail next week but here's the general idea. None of this is set in stone so feel free to vary any of these dimensions as you wish. Cut up a sheet of 3/4" birch or Baltic birch plywood into 3" tall strips with a 45 degree bevel on one side. This will give you 15 cleats @ 8' long. That's about $2.33 per 10' of cleat using birch plywood. Birch plywood is not nearly as tough as Baltic birch but it works. You can even use pine, poplar or hardwoods if you are sure you have access to wood that will not warp over time. I hang 40# material organizers on 1/2" Birch plywood and they have held up fine using 2 screws every 8". I suggest using 3/4" material so you don't have to worry about the cleat pulling away from the wall if you can only secure it every 16" or more. The photos below show a 1/2" cleat but I suggest using 3/4". Below you can see tool holders, box/cabinet holders, and a French cleat shelf bracket. The variations are as endless as your imagination but this should give you a good feel for how you can use French cleats to organize tools. Make sure you don't miss next week's article where I will introduce a new Shop Hacks product that will make building your own tool holders much simpler and faster so you can focus more time making, building and fixing and less time organizing. That should give you some great ideas to help you Build YOUR Space. Next week I'll show you more ways to implement French cleats and introduce a great new Shop Hacks product that will make the task much faster and easier for you.

Feel free to email me with questions, ideas or comments. I'm always interested in hearing what you are interested in so don't be shy. Check out other popular Shop Hacks Newsletters...

4 Comments

If you would like to receive FREE Shop Hacks like this every Friday at 3:30 Eastern Time... subscribe below... We've seen a number of drill/charger organizing stations over the past year on the Shop Hacks Facebook Group, but this one, designed by Shop Hacks member Tim Key, captured a lot of attention. It includes three useful features.

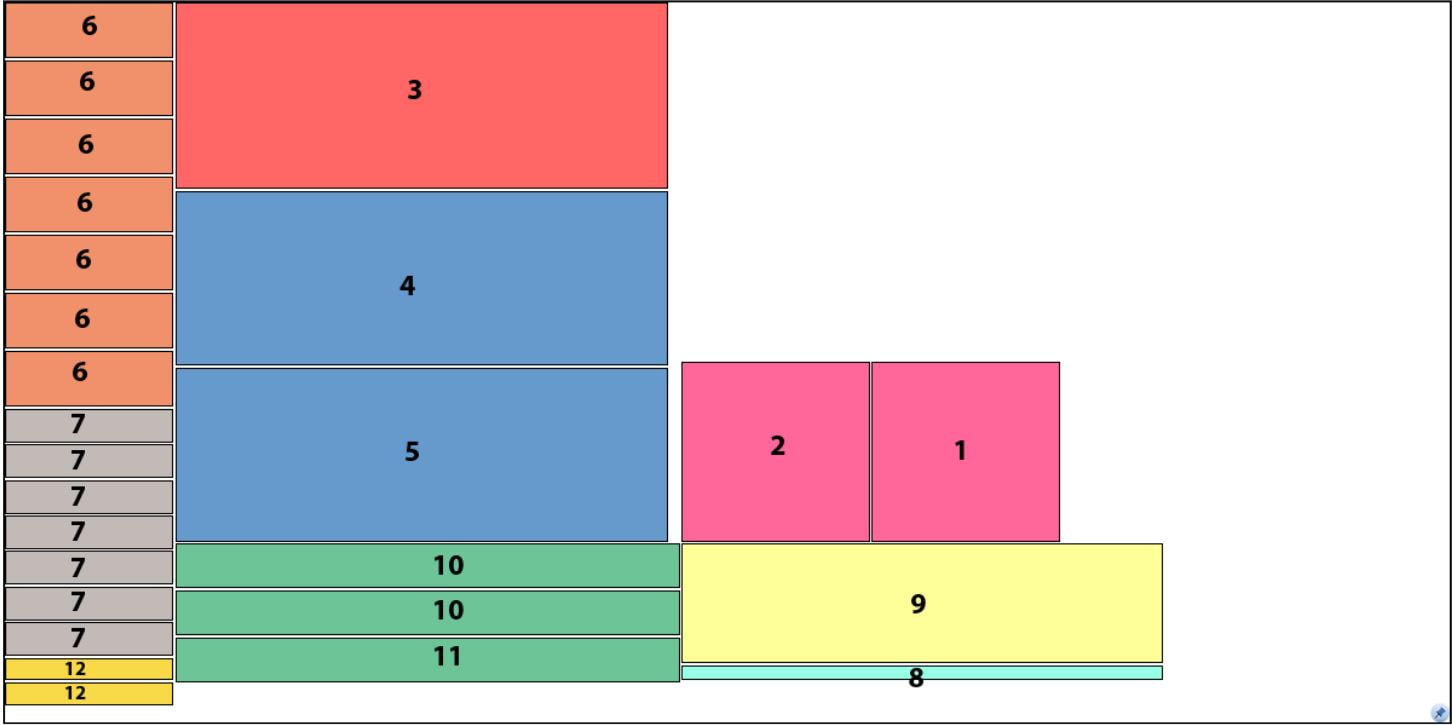

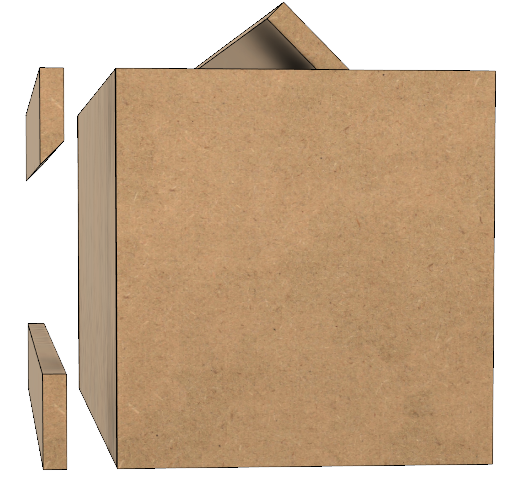

Let's Get Started Building YOUR Space! The first step is to break down your material per the following cut sheet. Order of cuts and specific dimensions are listed in the plans. Everything is based on 3/4" sheet stock. Tim used painted plywood and it turned out great. You can use any 3/4" sheet stock such as melamine, particle board, MDF or your preferred material. I like to use melamine. With edge banding it has a neat look and the light color has a way of making the shop much brighter once you start covering the walls with more and more white accessories. Baltic birch always looks great too no matter what you make with it. You can order 4x8x3/4 sheets of Baltic Birch through Menards if you have one local or your local lumber yard probably has it available. Note: Most sheet stock doesn't come in exactly 3/4" thickness. It can vary from 0.680" to 0.780" so make sure you measure the stock you use and adjust the dimensions outlined in the plans accordingly. If you would like to save time and make this build as simple as possible, you can support more content like this by purchasing plans for $4.95. The plans include the cut sheets, detailed dimensioned drawings, and tools and materials lists for this project. Shop Hacks is only sustainable through the generous support of those who purchase plans and hardware kits and through affiliate link income. SHOP HACK: Write each part number on a piece of tape and stick them to each piece so they are easier to keep track of later Cut Dados Next, cut the individual features into each piece. The plans include detailed drawings as well as 3D assembly and cross section views to make this step very simple. There are many ways to cut dados. I used a table saw and a Freud 6” x 10T Pro Dado Set (SD206). Another popular option would be to use a router and jig (video link). Cut all of the dadoes to half the material thickness. The grooves are 3/8” deep if you use ¾” material. If you use a material thickness other than ¾” exactly then adjust your cuts accordingly. Assembly If you plan to paint your drill organizer, it is best to do so prior to assembly. At least all the interior parts. Avoid painting the dado and rabbet cuts or you may have a hard time getting it to assemble flush. I got a little paint in them but was still able to get flush joints in my assembly. Bottom Shelf and Hangers Flip the bottom shelf upside down and flush the front against a straightedge that is at least ¾” thick. You want it to be easy to flush the front of the hangers with the front edge of the bottom shelf. I only glued the vertical hangers into place. I didn’t use any brad nails or screws. I glued and brad nailed the hanger bottoms with 1 ¼” brads. Get them all glued in and then clamp it down as best you can. I used another board and some weights and left it overnight. Side Panels, Back Plate, and Shelves This was the trickiest part of the build. My wife helped spread the glue quickly and helped hold parts together until I could get it into clamps. I used the following assembly process

Install the angled shelf lip on the top shelf. Flush the straight edge of the lip with the front edge of the charging station. Use 1 ¼” brad nails along the top flat area of the lip. There is no need to glue this in, but you can if you desire. This component is to keep the chargers from slipping off the angled shelf. There should not be a lot of force against it. To install the angled shelf, I used a DEWALT DWHT46031 Aluminum 7-inch Premium Rafter Square behind the shelf to hold the shelf at the correct angle while flushed the front edge up against the edge of the lip. I used 5/8” brad nails along the length of the angled shelf and the used 1 ¼” brad nails on the sides to maintain the angle of the shelf. There is no need to use glue on this shelf. Install the two end rail hangers. Glue the rabbet joints and use 1 ¼” brad nails to secure them in place. French Cleat Hangers If you aren't using French cleat hangers to secure your tool holders to the wall, this may be a great time to get started. French cleats are a very simple method to hang anything on the wall. It's a very simple system. Just attach a cleat with a 45 degree bevel to the top of the organizer as shown in the figure below. Attach a brace of the same thickness to the bottom of the organizer. Then, attach another cleat with a 45 degree bevel to the wall with the bevel facing up. Now you can hang any tool holder on the wall cleat which allows you to rearrange your tool holders as you are working through your preferred workflow. Install the French cleat flush with the top of the charging station using glue and 1 ¼” brad nails. Attach the mating cleat (not shown) to the wall using screws at the height you wish to hang it. The bottom board keeps the charging station square to the wall. Use glue and 1 ¼” brad nails to secure it to the charging station. The Power Outlet Cut a hole in the side panel on whatever side of the unit makes sense for your installation. I cut a 1 ½” hole. It needs to be large enough so that the wall plug can pass through. I used double sided tape to attach the power strip to the charging station. The paint would not allow hot glue to adhere to the station. Now you have a nice looking drill organizer that you can enjoy from now on. Don't forget to post a picture of your organizer in the Shop Hacks Facebook Group when you finish! We would love to see how you are Building YOUR Space! Zig Zigler once said, "You will get all you want in life if you help enough other people get what they want". That saying resonated with my core being and it is the basis of the Shop Hacks Innovators Program. My goal is to help as many of you build your dreams as I can while I'm building my dream. What is this program? In a Nutshell...

My hope is that this program allows motivated and innovative people like you to make money selling your product plans without the hassle and expense of the sales and marketing side. If you want to make $$ from your innovative and proven shop hacks then you will want to check this out. The draft details of the program are outlined HERE. I could have easily put plans together for my own version of Tim's drill organizer design and not split any of the profits. However, the thought occurred to me, "there is 1000x more collective talent in the Shop Hacks community than I have. They have talent and I have a marketing platform so why don't I work with these people in a way that can benefit all of us as a team". Let's partner to create something better than any of us could create on our own. Tim was using Sketchup (a low cost, entry level CAD software) when he first designed his drill organizer but was willing to jump in to learn Fusion360 (a more powerful and free CAD/CAM software). Having his design in Fusion made it easy for me to make the drawing views I wanted to use for the plans. He picked Fusion up very quickly and developed the CAD model and plans in just a couple weeks in his spare time. He put together the plans that are offered here and passed all of the information on to me to add the Shop Hacks branding. He's finished and is already working on plans for two more products. Without lifting a finger, Tim will accumulate residual income every quarter for as long as these plans continue to sell. I'm open to receiving ideas via just napkin sketches but the more work I have to do the less the royalty will be. However, all product ideas will be required to have the program steps completed prior to submission. Right now, for plans, I'm offering 50% of the profits for anyone who goes through all of the steps outlined in the program and summits a set of plans ready for release. We will start there but I will likely accept products that have fully functional prototypes without a CAD model or plans and offer a much lower royalty % . If this sounds like something you might be ready to invest in then go to the link above and read through the program outline. If you are still interested after reading through the program requirements, you will be directed to a link where you can join the innovators group to ask more questions, interact with other Shop Hacks innovators and brainstorm how we can make this program the most beneficial for everyone involved. I'm excited to help as many of you as possible to build your dreams, as I'm building mine! Shop Hacks Innovators Program Check out popular Shop Hacks Newsletters...

Promotion.... Build YOUR Space with these Shop Hacks products...

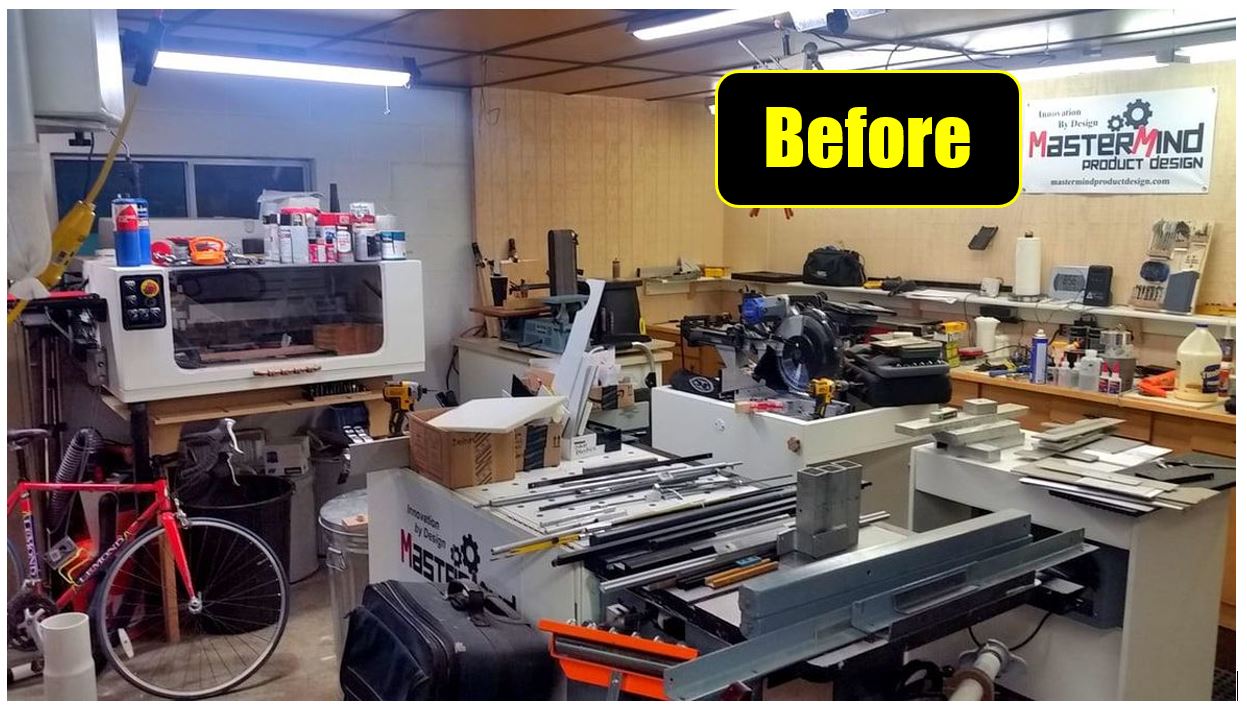

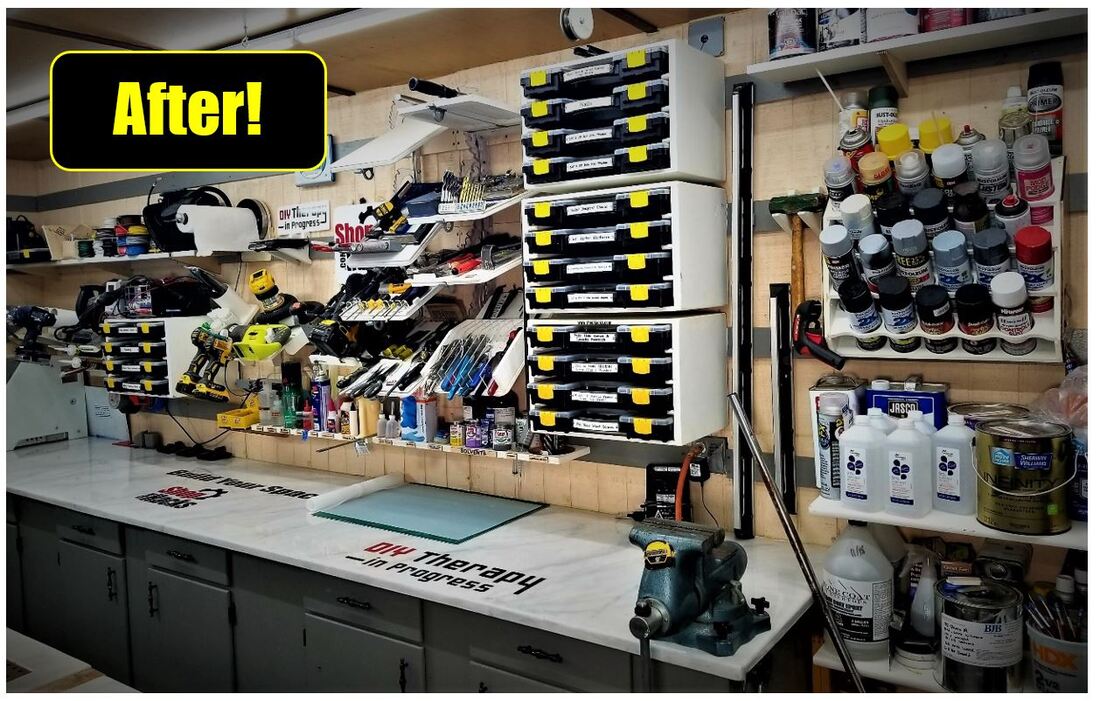

Workshop Organization - How to Organize Your Materials and Hardware Without Feeling Overwhelmed8/2/2019 If you aren't already subscribed and enjoy this type of content, you can subscribe to the weekly Shop Hacks Newsletter below. A sad but far too common shop related quote ... "I refuse to throw anything away, and never put anything back away. Eventually it gets so bad I don't even want to go in my shop." Does that sound familiar to you? We can all use some help organizing our workshop materials and hardware. Do you have a jar of screws that you just keep adding to thinking that one day you it will save your life? How about a scrap bin full of 20 years worth of off cuts that you are sure you will need one day? Have you ever started to organize that jar of screws or your many bins full of various hardware only to give up because there were just too many ways to sort them and it wasn't obvious at all which way you should choose? In today's article I'll show you how to organize common workshop materials and hardware. This article can help you get over the hump. I'll show you how I organized my hardware including pictures of several ways to store hardware and materials. Your workflow will likely dictate very different solutions than mine, but these ideas can be a starting point. Hopefully they will offer some extra encouragement to help you Build Your Space! The idea of getting organized is very exciting. The act of organizing is certainly not a fun task. Why would anyone go through the work needed to organize materials and hardware? Three years ago my shop was a disaster area. I reached a breaking point after tripping over some sheet goods for the thousandth time. They were stored in the path from the door to my main work area. The frustration of not changing finally exceeded the dread of making a commitment to change. I had no idea at the time how these changes would totally transform how much I enjoy my shop time. Check out the before and after pics below. These pictures will give you a feel for the difference a concerted effort can make and I hope they encourage you to take those first steps forward. You can do this too. I'll show you where to start and how to go about the decision making process and I'll share about the specific organizers that I use that transformed my shop. BEFORE: Piles of Materials EVERYWHERE BEFORE: Every Horizontal Surface is Covered up BEFORE: Paints, Solvents, Hardware in Disarray AFTER: Neatly Organized AFTER: FREEDOM!! Workbenches Free and Clear and my most used tools and materials are within arms reach All Materials and Hardware are in Labeled Locations and my shop stays like this all the time now that it's so easy to put everything away. Why Get Organized?? When I look at these 3 year old pictures of my shop, I realize that I've already forgotten how I worked for almost 30 years. I would NEVER consider working like that now that I've experienced a whole new level of workshop enjoyment. In the past my shop would get very disorganized. I would cover every horizontal surface with tools and materials again. Then, occasionally, I would spend a couple hours rearranging junk so it felt more organized (but nothing like it is now). I was always fighting for working space and wasting time. How much time does it cost to be disorganized? One of the most common sayings I hear all the time is, "My shop is a mess but I know where everything is.". That may be true but you are still wasting a lot of time if you are keeping unused items in your active work areas and if the items you use 80% of the time are not within arms reach. Think about how many times an hour you have to walk to get a tool or a piece of hardware. Let's just assume that you walk 10 ft to get a tool or some piece of hardware or material at least 15x per hour that you work in your shop. That's probably a low estimate for most of us. Assuming it takes 20 seconds to get what you are looking for that's close to 5 minutes per hour wasted on motion and hunting for things. Let's just say 10% for an even number. If you look at the photo above you will see that I have pared my tools and materials down so that the items I use 80% of the time are within arms reach. Compared to my previous setup I now get to spend 10% more time making, building and fixing things vs. cleaning, sorting and hunting. I spend around 2,000 hours a year in my workshop so that adds up to around 200 hours (5 full weeks) that I get to spend on projects vs wasting time hunting. Let's say you spend 10 hours a week in your shop. Using the same numbers as above... Organizing your tools and materials can allow you to spend over 50 more hours each year doing what you love vs. walking around, hunting and sorting! What would you make in your shop if you had an extra 50 hours per year to spend without taking time away from anything else? What Should You Do First? As I mentioned earlier I had several false starts when I tried to organize my shop. If you try to organize everything you will fail. Work on one work area at a time. The more organized I get the more I realize that less is best. This is why it is imperative that you only try to organize what you physically touch over 10 sessions or so in any particular work area. If you haven't touched tools, hardware or materials in that work area in the last 10 sessions in your shop then trust me, it needs to go into a storage area or out of your shop. Save room for the tools, materials and hardware that you use 80% of the time in each work area and mount them all within arms reach. I previously wrote an article about How to Organize Your Tools Without Feeling Overwhelmed. In that article I show you how to pare down the tools to increase your efficiency and buy back as much as a full week per year of extra project time without taking that time from anything else. Click on the link to get more details about how this principle makes everything about organizing your shop much easier and more efficient, including hardware and materials. Organizing Your Hardware The first organizing task that I completed was to organize my screws and other small hardware pieces. If you want to succeed you will have to make some uncomfortable decisions to get everything you don't touch on a regular basis out of your work areas. You got where you are with comfortable decisions. If you want to spend more time doing what you love and less time hunting and sorting then you will eventually have to do this anyway... empty your junk drawers, jars, etc... into the garbage. If you just can't bring yourself to do that then put them away in a storage area that doesn't use valuable space but get everything out of your work area to start with. Unless you have expensive hardware that you already have slated for a specific project you are better off starting with a clean slate. You can buy hardware relatively cheaply at Harbor Freight or Tractor Supply so don't hang on to your random assorted hardware. Put together hardware bins and organizers It is easier to show you what I did than to try to explain it. I'll show you what I ended up with for every organizer.

4. I labeled every bin and placed them with the ones I use the most frequently closest to me. Below are 4 sets of 4 organizers that I felt were worth keeping in my active work area within arms reach. I stored everything else away from my work area. Organizer bin labels I created: Bin #1

Pictures of the contents in each hardware organizer: I should reiterate that your setup will most likely look totally different than mine. I ended up using about half of these on a frequent basis so I could have saved some time and just put the rest in storage. It doesn't hurt to have to walk to a storage area for something you only use occasionally. However, it saves a lot of time to have everything you use frequently within arms reach. Organize only the items that you actually touch and store or purge the rest. I store refills for frequently used hardware in a storage area. I used the Harbor Freight hardware organizers. They have held up very well and I can recommend them for in shop use if you have a Harbor Freight store in your area. If you don't have a Harbor Freight store near you or if you want something more durable for rough use then you might be interested in one of the higher end sets listed below. Disclosure: The products listed are affiliate links. By using these links you won't pay any extra but Shop Hacks will receive a small commission on each purchase. Thank you for your support that enables me to continue creating these articles to help you Build Your Space! If money is no object then you might consider investing in the Festool Sortainer system

If you are content with a very good and durable system but don't want to spend 3x as much for it then the Sortimo T-BOXX G was highly recommended in the Shop Hacks Facebook group.

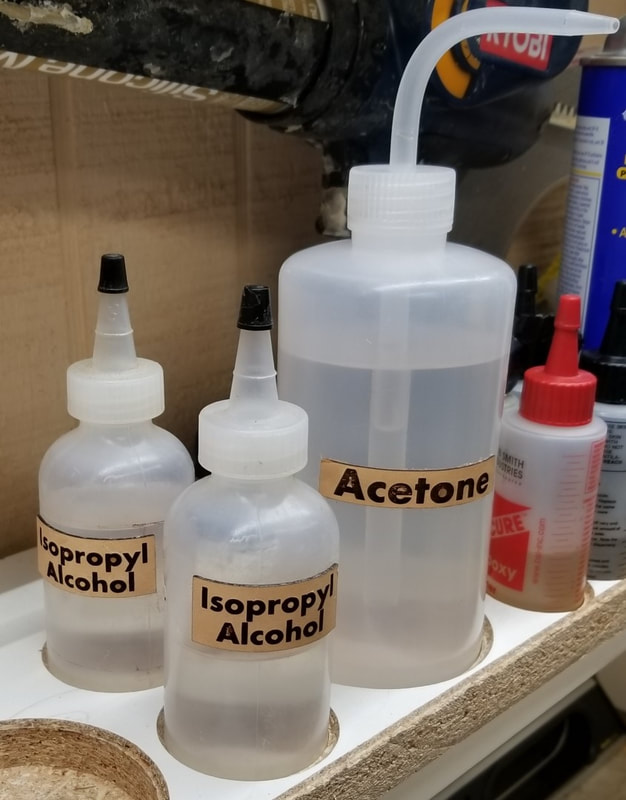

Spray Paint Can Storage... I used to keep my spray cans in an old refrigerator but I found that I didn't like having to bend over and move the cans in front to see what I had in stock behind them. I designed the rack to pack the cans as closely together as I could. It hangs on a French cleat which makes it easy to relocate. I've relocated it a couple times already. Some people would prefer to store volatile compounds in a flame rated cabinet and I can see their point, but I prefer this method. Adhesives and Solvent Storage... I originally stored my paints, adhesives and solvents on shelves. I had to walk half way across the shop just to use them. I paid attention to which ones I used the most often and made simple routed pockets in melamine boards for them. Every location is labeled so I know what is missing. Without labels most of these organizing systems fall apart so don't skip this step. This may seem like an inconsequential change but it has saved me many hours in just a couple of years now. I haven't had to change any of the boards to accommodate different shaped containers yet but, if I do, I can easily modify the CNC file and cut another one out in 10 minutes. Before and after pics below... Sheet Goods Storage... Unfortunately I don't have any pictures to show the "Before" chaos in my shop. I tried three different methods to store my sheet goods.

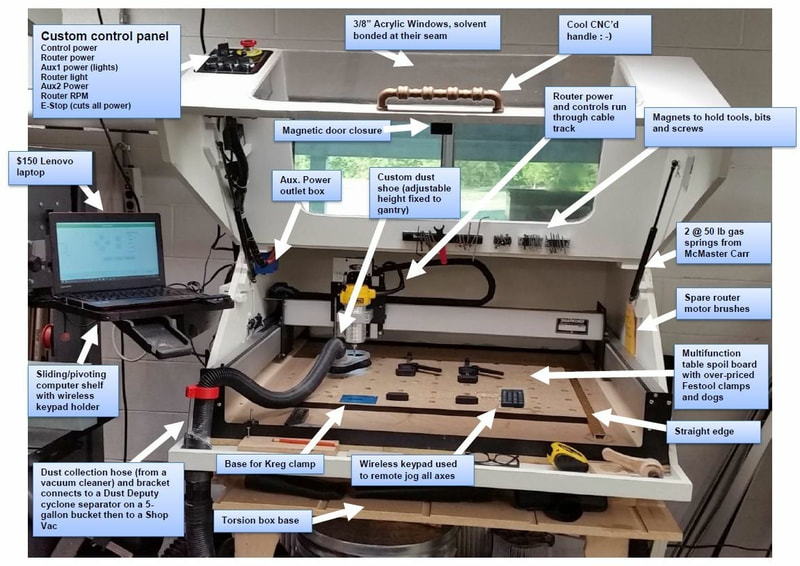

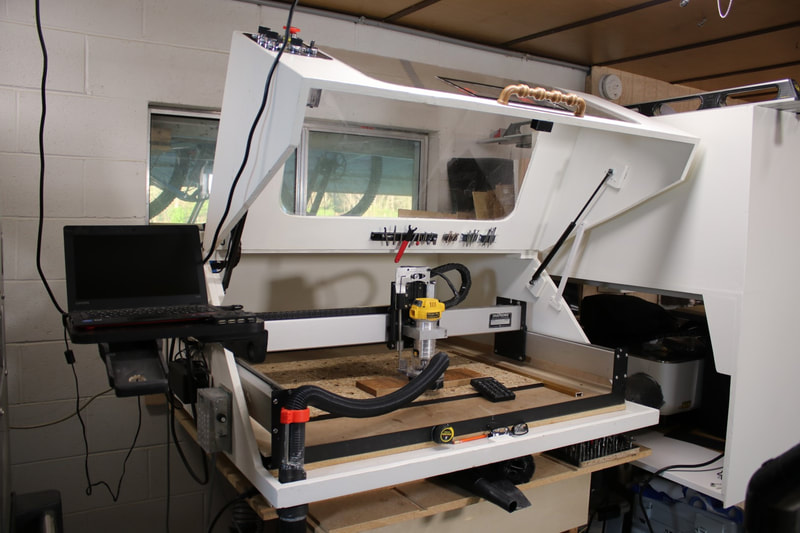

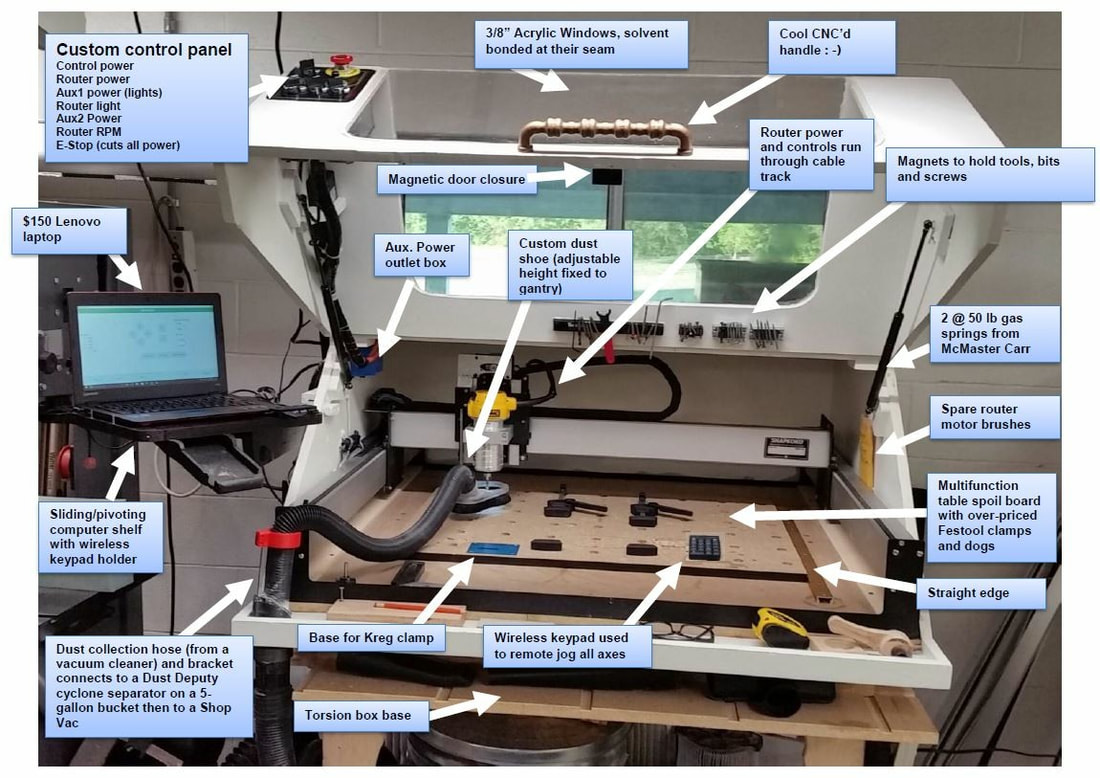

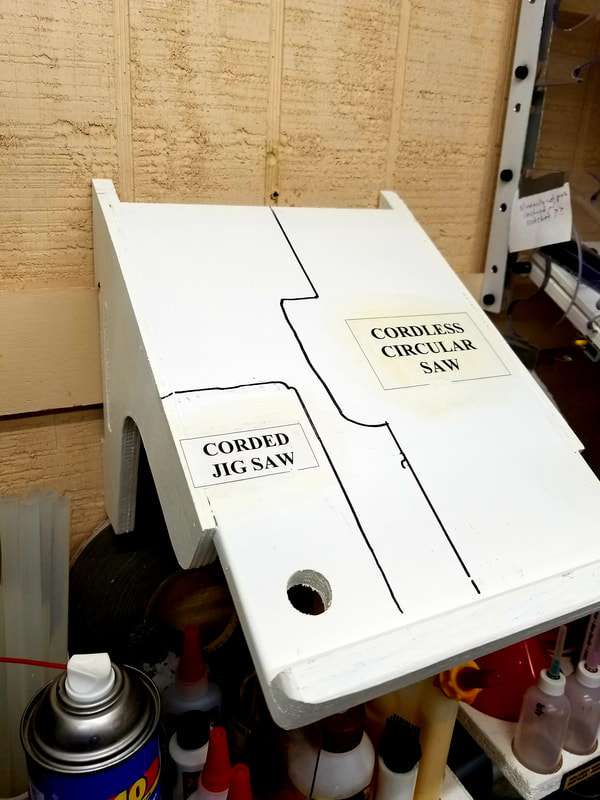

I didn't like having to lower the rack and move things just to get to something in the rear. I found that I often would forget about stock that was stored here because it wasn't easy to see everything at a glance. Cool innovation but unfortunately it wasn't very practical for my work flow. The sheet goods storage method I like the best so far... Sometimes the simplest way ends up being the best way. I can easily pull out any sheet I want without moving or lifting around another sheet and I can easily see everything I have available to use with a single glance. CNC Router Work Area... I use my CNC router a lot so I didn't want to have to walk to another area to get anything that I used for CNC tasks. Except for a drill and driver I have everything I need within arms reach of my CNC. I almost always screw my stock to the waste board so I have various length screws mounted on magnets in the lid. Various fixtures and hardware are stored in a drawer just below the CNC. Bars, Rods and Tubing Storage... I don't use bars, rods and tubing very frequently but just frequently enough to justify storing them in my shop. Below are some before and after pictures. The organizer is on a lazy Susan bearing so I can rotate it to access any of the stock I need without reaching around anything. I have quite a few other organizing systems in place but this should get you started with plenty of ideas. Start with one small set of hardware and work your way out. I can guarantee you that you will enjoy working in your shop more than ever once you follow the simple methods that I've laid out in this article as well as in the How to Organize Your Tools Without Feeling Overwhelmed article.

If you enjoyed this article and want to receive weekly tips like this via email, you can subscribe to the the Shop Hacks Newsletter . If you want to see new shop hacks every day then join the Shop Hacks Facebook group! Please comment in the area below this article if you find something that you like, have a tip to share, or if you have any questions. Comments are a great way to share knowledge and they let me know what you care about the most for future content.  Do you love to spend time in your shop, garage, or work space? We value every second that we get to spend in "our space" even if it is a mess. It's a place where we can just relax and enjoy time away from everything else with no expectations other than our own. Would you like to have someone show you a way to organize your tools that is easy to understand and implement? Would you like to get 25 extra hours to work on your projects every year without taking time from anything else? Would you like to enjoy working in your shop even more than you do now? In this article I'll show you how do just that. Next week's article will cover organizing your hardware and materials. If you have missed previous Shop Hacks articles, you can find them through the links below. If you aren't already subscribed to the Shop Hacks Newsletter, just click the button below to get weekly Shop Hacks sent to your email. You can opt out at any time. Do you feel frustrated that your shop is a mess and you are always walking around things and have to sift through piles of tools and materials on every horizontal surface? Have you ever tried to tackle tool organization in your workshop only to give up in short order because you felt overwhelmed just trying to decide what to organize, where to put it and how to hold it? You certainly aren't alone. The photo below shows the chaos that was my shop when I finally reached my breaking point and made the decision to put my head down and get it organized, do or die. I was tired of walking around things and wasting so much time hunting for tools and materials and seeing every horizontal surface stacked with piles of "stuff". I had a may false starts and several failed attempts. In this article I hope to save you a lot of time and avoid the headaches that almost made me give up before I finally succeeded. Using the 10 step method in this article, you can complete the process without feeling overwhelmed. I'll show you how to estimate how much time you can buy back through organization as well as how to implement the plan. Your solutions will be completely different than mine but this process will work with any work flow and with any organization system that you choose to use. An Important Note I think it may have been Adam Savage who said, "drawers and cabinets are where tools go to die". There's truth in that statement because what is out of sight is often out of mind. I chose to use an open storage system for my tools. This saves the time of opening a drawer or door every time I want to use a tool and put it away. This works in my shop because I have modified my dust collection systems to the point that the air in my shop stays cleaner than the air outside. That allows open storage without dust building up on everything. If you don't have effective dust collection and air filtration in your shop then you may want to consider using cabinets and tool boxes to keep the dust at bay until you get a chance to get your dust under control. I'll shared how I did so in my shop in future articles. The Shop Hacks 10 step system will work regardless of how you plan to store your tools. The principles and method are the same regardless of how you implement them. I worked on organizing my tools and materials one group at a time until all of my active work areas were well organized and every tool in each of those areas had a marked location. The secret to establishing order was to pair down the tools and materials to those that I touch on a regular basis and to put everything else out of my work areas and into storage. LESS is MORE in this case. The key maintaining this order for almost two years now is that every tool and all materials have marked locations. I could not have imagined how much more I was going to enjoy working in my shop after I made these changes. The difference is tremendous. I work more efficiently but, more importantly, I enjoy using my shop more now. It's like the difference between using an old worn out tool that you have to stop and fix all the time and using a quality new tool that does the job just the way you want every time. We love our shop time because it's our time, so why not make the most of it? I have everything I need for each task close at hand. I can grab most tools now without even having to look at them. It is also much easier to keep my work spaces clear of piles of tools and materials now that a simple lap around the shop with an arm load of tools at the end of the day, filling in open tool slots, is all it takes to put everything back like it was when I started. That's something I could never do before. Moving from chaos to order is not easy, but it is extremely rewarding. It is worth the work and it pays dividends for life. Try to work on one area at a time so you can build small victories that you will need to carry momentum through this process. This is a big job. Look at it as a process that takes time and iteration. To prevent burnout, expect changes and don't aim for perfection right away. The following quote by Mark Twain sums this up very well... "Continuous improvement is better than delayed perfection" Mark TwainHere is a summary of 10 steps that will allow you to organize your tools and transform your workspace without feeling overwhelmed. I'll cover each step in more detail in the following sections. I encourage you to print out several copies of the checklist below and place one in each work area that you frequently use. When you are ready to start organizing that work area fill in the start date and start working through the list one step at a time, not skipping any steps. When you finish one of your work areas, fill in the finish date and post a copy in the Shop Hacks Facebook group with before and after pictures. We would all be so encouraged to see hundreds of these posted over the next year!! Tool Organization - The Shop Hacks 10-Step Program (details provided in each of the following sections) Work Area _____________________ Start date: __________ Finish date:_________

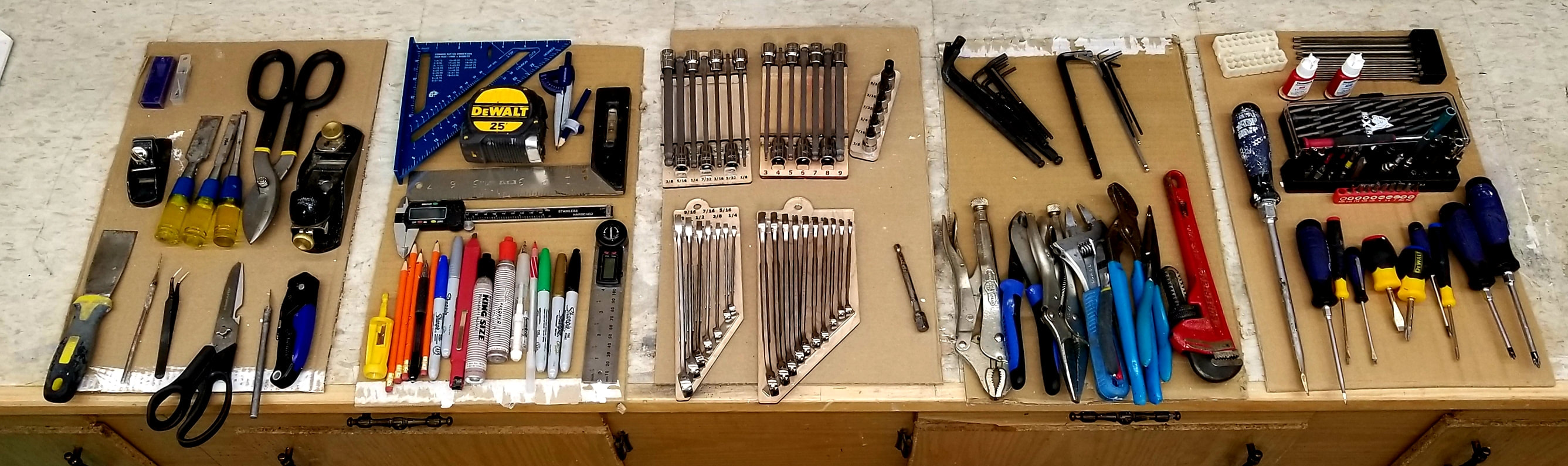

Step 1: Clear off a horizontal surface large enough to hold every portable tool that you will use in the next 10 sessions in one of your work areas. Make sure this area is separated from adjacent areas and make sure it is a space that you won't need for anything else. Consider this your tool box over the next 10 work sessions. It helped me to mark this area off with masking tape to designate the area exclusively for this purpose. Ideally you will block this area off for at least 10 work sessions so pick an area that you can spare for that long and make sure it is large enough to hold a pile of all of the portable tools that you will use during this time. Step 2: Store EVERY portable tool that you use over a period of 10 work sessions (and nothing else) in this designated area. The ultimate goal for each active work area is to place ONLY the tools that you use 80% of the time within arms reach and put EVERY other tool that was in that area outside of that area in a storage location. I use a utility room, shelves and a large toolbox to store the items that don't make the cut. This buys back days of work time per year. I can't emphasis enough how much better it is to store as few tools as possible in your active work areas. This frees up your tool wall as well as your mind. Less is more. It's okay to store the remaining 20% away from your active work areas. Walking 15' to retrieve them doesn't cost much time overall because you don't have to do so very often. Here's an example to objectively demonstrate how simple, organized, open storage can buy 25 more hours per year doing what you love: Let's say you use 5 different sets of pliers 80% of the time and 10 other types of pliers the other 20% of the time.j Scenario 1 = organized open tool storage of those 5 sets (ONLY) at arms reach Scenario 2 = Toolbox or drawer storage 10' away from where you are working Time to retrieve = Scenario 1: 1 second if they are at arms reach Scenario 2: 10 seconds if you have to walk to a toolbox, open a drawer and walk back. Use the pliers 500 uses over 50 work sessions Time wasted in each scenario: Scenario 1: (500 uses * 1 sec/use) = 500 seconds or 8.3 minutes of wasted time Scenario 2: 50 sessions * 20 seconds (retrieve and put back) + 500 uses * 1 sec/use) = 1500 seconds or 25 minutes of wasted time. You can save over 15 minutes per year for every tool that you place within arms reach vs. walking to a toolbox to retrieve it. Multiply this by 100 tools and you gain around 25 hours/year doing what you love vs. walking and hunting in your shop every decade with one simple change. Let's get started and buy some time!! During your next 10 sessions in a work area place every tool or set of tools that you physically touch into the area that you designated in Step 1. It doesn't matter what kind of tool, if you touch it then put it in this area. Consider this your toolbox for the next 10 sessions in your shop. The picture above shows the tools I used during that time. The type and number of tools will be completely different for everyone so your pile will most likely look nothing like mine. Do NOT put any tools there unless you actually used them. This objective approach will make it easier to separate what you "feel" like you need to organize and what you really "need" to organize to save time which is our primary goal. Don't worry about missing something during this step. You will have a chance to evolve and adjust this system in later steps before you spend a lot of time making or buying tool holders. In general, don't store ANY tools (or sets of tools) in an active work area that you don't physically touch at least once in every 10 work sessions. Trust what you actually touch and use and not what you think you will use. This step is essential to objectively decide vs. making subjective decisions which inevitably lead to wasted time. Start small so you can get a feel for this process and build up some confidence. Do not try to organize your biggest work area or you will probably get frustrated and give up. Small victories will build momentum. Maybe you just try this for a sanding area to start with to get the hang then try an assembly area next and then work your way around the shop applying the 10-steps to each area. What is an active work area? An active work area is any place that you spend a significant amount of time performing any activity. The following are just a few examples...

Don't worry that you may leave something essential out. The following steps leave plenty of opportunities to add more tools as you work through a variety of projects. Your goal here is to build a pile of tools that represent what you actually use 80% of the time in your shop without being subject to your subconscious tricking you into believing you need more. Don't put a tool in this pile if you did not actually use it. Trust me. Step 3: (this is probably the hardest step to do, but it is one of the the most important) Put ALL of the tools that you did NOT use in a storage area separated from your main work area This step may go against every fiber of your being. We are hardwired to put every tool we own on display. But if you want to spend more time creating, building and fixing and less time hunting and sorting then don't give into the lie that having more tools on your tool wall is better. Less is more! Now that you have a pile of tools that you used in a particular active work area, put every other tool away in storage or give it away or throw it away if it isn't useful to anyone. If you can't bring yourself to do this then you aren't ready for the Shop Hacks 10-Step Program and we will be forced to exercise tough love and let you suffer in your disorganized mess until you are truly ready to change ;-) Seriously though, trust me and give this whole process a shot. If you don't like it you can always add more at the end. Your tools will still be seconds away. Step 4: Sort the tools that you used into functional groups This step was difficult for me. There are so many ways to group tools and I ended up trying several layouts before I was comfortable with what I had. Don't feel like you have to get this right the first time. In later steps I'll show you how you can try many different layouts without wasting much time. For instance, over a 1-year period I ended up sorting my tools into the following groups:

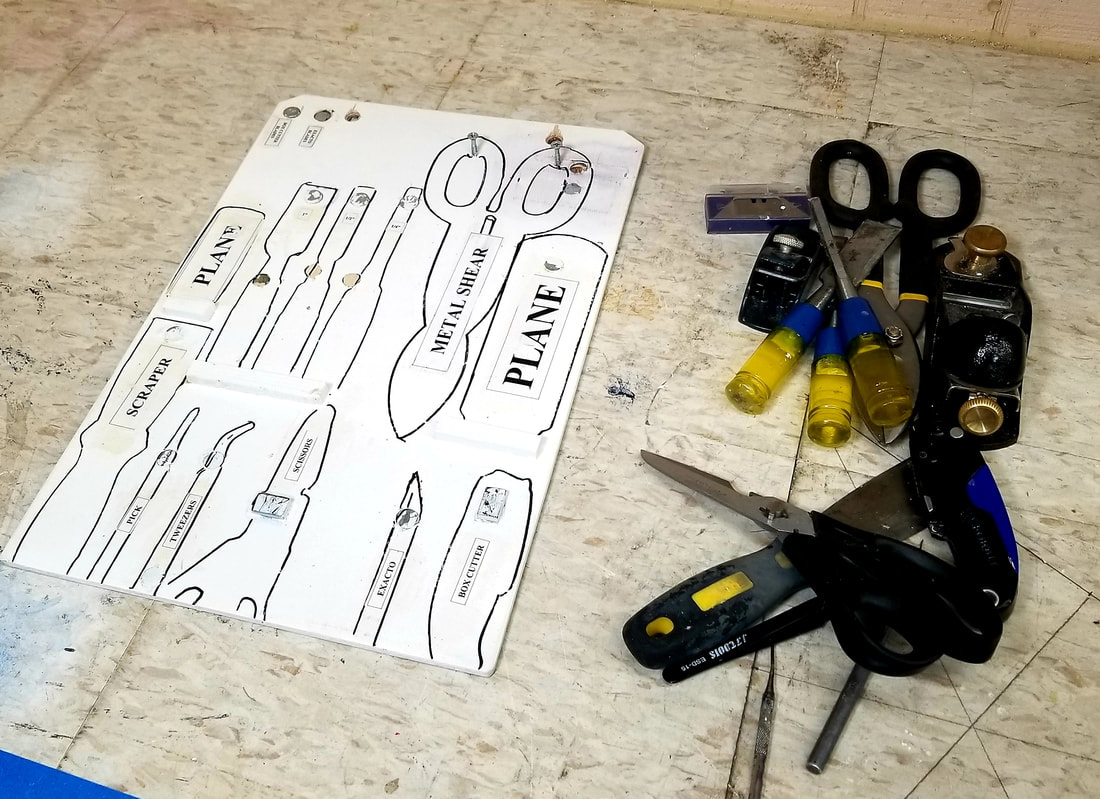

The group names and which tools go into each group will be completely custom to the way you use your tools and which tools you have at each active work area. You will get a chance to try out and adjust your tool groupings later so don't worry about getting them perfect on the first try. Pursuing perfection will cause paralysis, so just move forward and adjust anything that you don't care for in a later step. I'll cover how to sort your hardware and supplies in next week's article. You can see most of the tool groups that I ended up choosing in the picture below. This photo also shows the Shop Hacks Ultimate Flip Top Workbench which serves as a workbench, downdraft table and assembly table 95% of the time and flips to transform into a miter saw station with the Chop Stop fenceless miter stop system 5% of the time. This flip top workbench has been a great addition that adds convenience and efficiency to my workflow. The wings fold down and it has a electro-hydraulic lifting mobile base which makes it super easy to move around with just push of a button. Click on the link above to see options for plans, hardware and the Build With Confidence Support group. The photo below shows my CNC router work area. I have everything I use 80% of the time within arms reach and the rest is in a drawer under the base of the router (drawer added after I took this picture). I also made holders for the handheld power tools that I use the most as shown below. Everything on my tool wall is hung on a French cleat. These are just a few examples. The key is pairing down to the tools you will actually touch frequently and sorting them into groups based on how you use them so you can keep tools as close to your active work areas as possible. Step 5: Cut multiple pieces of cardboard to serve as mock tool panels. This is the easiest step of the process. Determine how large you want each tool panel to be and cut pieces of cardboard to those sizes. I chose to make all of my panels 11"x17" because that allowed multiple tool panels to fit into any of my toolbox drawers. As it turns out, using this system I was able to mount ALL of them on my tool wall and I very rarely have to get anything from my toolbox anymore. Step 6: 1. Organize your tools on each mock tool panel. Use them for a while like this then iterate until you are happy with the layouts. This step is also very simple but may take some time. The idea is to try out your layouts before you commit a lot of time to building tool panels to mount your tools. I kept my tools laying on these cardboard panels like this for a couple of months as I used them. I put the tools back on their designated panel after I finished using them each day. If I didn't like where or how a tool was placed I simply rearranged and regrouped them as I went. This let me test out my layout before spending a lot of time building the tool panels. I found that I had to add some tools that didn't make the cut during earlier steps and I also removed some tools that were not getting used. Once I was comfortable that I had my tools paired down to ONLY the ones I use 80% of the time, I moved on to the next step. I should note, even though I went through all of these steps I still ended up making some changes later on. However, the changes were minimal and didn't take nearly as much time as they would if I would have had I not tested my layouts before building the tool boards. Step 7 Buy or build permanent tool panels and mount your tools These are a couple of the tool holders that I made to hold my tools. These were built using 1/4" Baltic birch plywood panels and 3/4" cleats to connect to French cleat rails on my tool wall. There are several very nice premade tool organizations systems available if you want to save some time by using a ready-made system. I'll include some options to consider below. The following products are affiliate links. When you use these links you pay the exact same price that you would otherwise pay but Shop Hacks receives a small commission for the purchase. Using these links is a great way to support more content like this in the future. Thank you for your support!

Step 8 Mark EVERY tool location. You may be tempted to skip this step but don't... It is a game changer. This is another very simple but very important step. I tried several methods. The easiest one was to simply mark an outline of each tool using a permanent marker. I intended to come back and make something more refined but this worked so well I never felt compelled to change it. These tools are held in place with neodymium magnets. Some of the larger items use mini stop blocks too. Another unique way to mark tool locations is to take a photograph of the tool board and glue the photos onto each tool location using a spray adhesive. This works great but it is time consuming. Using marked locations for tools is great at the end of the day when you just scoop up a handful of tools and take a lap around the shop filling in empty marked locations. There's something very satisfying about doing this. I rarely end a day anymore without putting all my tools away. Before I had a specific marked location for every tool I rarely put tools away and I ended up having to shuffle tools and materials around for 10 minutes just to get started the next morning. Not to mention the time wasted trying to remember where I put things. Neodynium magnets are great to have around anytime you want to build a tool organizer. Step 9 Store your tool panels near the locations the tools will be used.  I can't overstate how important it is to keep 80% of the tools you use in any active work area within arms reach of where you use them most of the time. It saves a lot of time but another benefit is that it makes your work more enjoyable. You may be used to walking back and forth across your shop to get tools to make or fix something but once you get used to being able to reach almost everything you need without moving you will wonder how you ever worked any other way. Step 10 Repeat this process as needed until you've worked through all of your active work areas. Start with small organization tasks to build momentum. then work your way to the active work areas that you use the most and get those worked out. Keep going until you've organized all of the areas that you frequently use. After that you can keep going but you have diminishing returns. I still have quite a few areas of my shop that need to be organized but just having the areas I use 80% of the time worked out has made all the difference.

Have fun, enjoy the process and eat this elephant one bite at a time. Please leave comments below. I encourage you to ask questions, share your own organizing tips and share what you would like to see in future articles. Affiliate links may be used on this page. As an Amazon Associate I earn from qualifying purchases. Shop Hacks exists to help you Build YOUR Space! |

Categories

All

NewsletterShop Hacks exists to help you Build Your Space! Archives |

- Home

-

Improve your Workspace

-

Dust Collection and Air Filtration

>

- Table Saw Dust Collection

- All About Cyclone Separators

- Dust Deputy and Dustopper Review and Comprehensive Scientific Testing

- Dust Sheriff Cyclone Separator

- Dust Collection System Options

- Air Filtration System Options

- Why clean air matters

- Is your shop air safe???

- How to maintain healthy air in your shop

- Dust Collection Resources and Links

- Why I became obsessed with dust collection and air filtration

- Storage, Organization, Efficiency >

- Improve your workshop floors and lighting >

-

Dust Collection and Air Filtration

>

-

Improve Your Tools

- Shop

- Contact

Get weekly blog articles and early bird discounts for new products

through the Shop Hacks Newsletter. Every Friday at 3:30 Eastern Time.

SUBSCRIBE to the weekly Shop Hacks Newsletter

through the Shop Hacks Newsletter. Every Friday at 3:30 Eastern Time.

SUBSCRIBE to the weekly Shop Hacks Newsletter

Site Map

© Copyright, Shop Hacks 2019

RSS Feed

RSS Feed