Common Dust Collection System Options

Overview

In this article I'll cover pros, cons, options and performance considerations for shop vacs, dust extractors, and dust collectors.

The three common systems used for cleaning and dust collection -

Shop Vacs, Dust Extractors, Dust Collectors

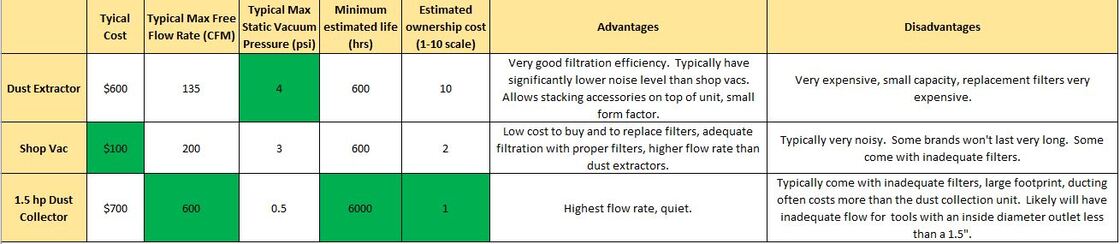

Typical cost and performance ranges for each are listed below. I'll cover the pros, cons, and performance specs for each system in this article. These categories are generalizations and you can find many more variations. However, these are the most commonly used systems and specifications used for home shops.

Shop vacs - $50 to $150, 50-200 cfm flow rate, 1.5 to 3.5 psi max static vacuum pressure. Expected life - 300 to 900 hours.

Common brands: Ridgid, Shop Vac, Craftsman, Stanley, Vacmaster, etc...

Dust extractors - $250 - $700, 120-150 cfm flow rate, quieter than most shop vacs, include features not found in shop vacs, 4 psi max static vacuum pressure. Expected life - 300 to 900 hours.

Common brands: Festool, Fein, Bosch, Makita, etc...

Dust collectors - $250 - $X,000, 600-3000+ cfm flow rate, require bulky hoses and ducting, 0.2 to 0.5 psi max static vacuum pressure. Expected life - over 6000 hours.

Common brands: Grizzly, Powermatic, Jet, Shop Fox, Delta, Oneida, Rikon, etc...

In this article I'll cover pros, cons, options and performance considerations for shop vacs, dust extractors, and dust collectors.

The three common systems used for cleaning and dust collection -

Shop Vacs, Dust Extractors, Dust Collectors

Typical cost and performance ranges for each are listed below. I'll cover the pros, cons, and performance specs for each system in this article. These categories are generalizations and you can find many more variations. However, these are the most commonly used systems and specifications used for home shops.

Shop vacs - $50 to $150, 50-200 cfm flow rate, 1.5 to 3.5 psi max static vacuum pressure. Expected life - 300 to 900 hours.

Common brands: Ridgid, Shop Vac, Craftsman, Stanley, Vacmaster, etc...

Dust extractors - $250 - $700, 120-150 cfm flow rate, quieter than most shop vacs, include features not found in shop vacs, 4 psi max static vacuum pressure. Expected life - 300 to 900 hours.

Common brands: Festool, Fein, Bosch, Makita, etc...

Dust collectors - $250 - $X,000, 600-3000+ cfm flow rate, require bulky hoses and ducting, 0.2 to 0.5 psi max static vacuum pressure. Expected life - over 6000 hours.

Common brands: Grizzly, Powermatic, Jet, Shop Fox, Delta, Oneida, Rikon, etc...

Hover over or click on the images above to see information regarding each of the systems shown.

Special Considerations

1. Very few tools have effective dust collection ports. UNLESS you modify your dust collection ports to capture the dust within 1" of where it exits the stock, you will need to use a 600 cfm (or higher) dust collector to achieve effective dust collection from some of your tools.

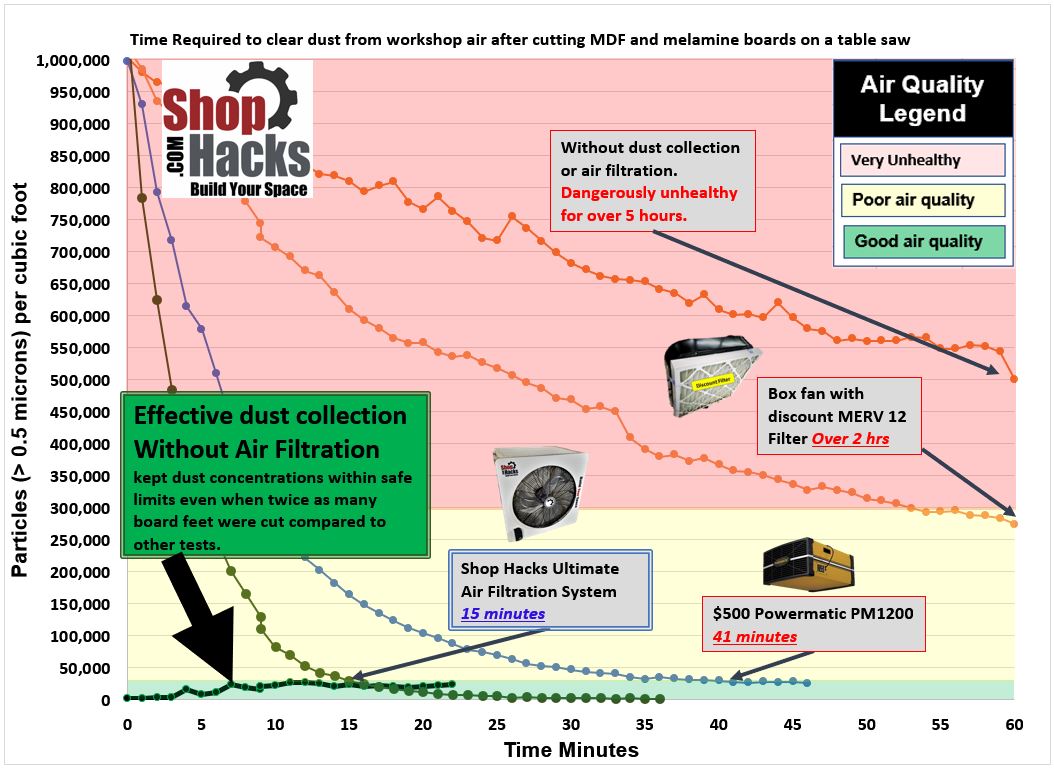

2. Fine dust and smoke stays suspended in the air for up to 5 or 10 hours after it is generated. Even with an effective dust collection system you need an effective air cleaner system to bring the particulate levels down below safe levels as quickly as possible when dust or smoke escapes during some operations. With a properly sized air filtration system you can decrease your exposure to dangerously high particulate levels from many hours after each operation to less than 15 minutes. Click on the link to read more about air filtration systems. The Shop Hacks Ultimate DIY Air Filtration System will clean your shop air faster than 2 Powermatic PM1200 systems costing $500 each. You can build the Shop Hacks system for under $200 in an afternoon with a saw, router and a drill.

PRO TIP:

For better dust collection with less flow, modify your tool ports to capture the dust within 1" of where it is generated. If you catch the dust or smoke 2x closer you can use 4x less CFM, 3x closer = 9x less CFM, 4x closer = 16x less CFM... you get the picture.

For an example of one tool modification, click on the following link to see how to achieve effective dust collection with any table saw using only a small shop vac. If you modify your tool ports to capture dust close to the source, you will achieve more effective dust collection with 100 cfm than you can with 1200 cfm positioned 6" away from where the dust comes off of the stock.

Dust will settle on its own but the finest and most dangerous dust can linger in the air for up to 10 hours. However,

1. Very few tools have effective dust collection ports. UNLESS you modify your dust collection ports to capture the dust within 1" of where it exits the stock, you will need to use a 600 cfm (or higher) dust collector to achieve effective dust collection from some of your tools.

2. Fine dust and smoke stays suspended in the air for up to 5 or 10 hours after it is generated. Even with an effective dust collection system you need an effective air cleaner system to bring the particulate levels down below safe levels as quickly as possible when dust or smoke escapes during some operations. With a properly sized air filtration system you can decrease your exposure to dangerously high particulate levels from many hours after each operation to less than 15 minutes. Click on the link to read more about air filtration systems. The Shop Hacks Ultimate DIY Air Filtration System will clean your shop air faster than 2 Powermatic PM1200 systems costing $500 each. You can build the Shop Hacks system for under $200 in an afternoon with a saw, router and a drill.

PRO TIP:

For better dust collection with less flow, modify your tool ports to capture the dust within 1" of where it is generated. If you catch the dust or smoke 2x closer you can use 4x less CFM, 3x closer = 9x less CFM, 4x closer = 16x less CFM... you get the picture.

For an example of one tool modification, click on the following link to see how to achieve effective dust collection with any table saw using only a small shop vac. If you modify your tool ports to capture dust close to the source, you will achieve more effective dust collection with 100 cfm than you can with 1200 cfm positioned 6" away from where the dust comes off of the stock.

Dust will settle on its own but the finest and most dangerous dust can linger in the air for up to 10 hours. However,

Pros and cons of each type of system in detail...

Shop Vacs

Unique Benefits Shop Vacs Offer

1. They are the cheapest option available. Quality new shop vacs cost $100 to $150. You can easily find a good used shop vac for under $30. Add a high quality filter for about $20 and you have an effective way to control dust in your shop for $50 total.

2. They are offered in a very wide range of sizes and flow rates.

3. Cordless models are available

4. The largest shop vacs flow more cfm than dust extractors

5. Shop vacs can be used to clean up anything including dust, rocks, water, metal. Pretty much anything that is not hot and that will fit through the hose can be vacuumed up using a shop vac with no worries of damage.

Accessories

Shop vacs are very popular option because they are inexpensive, portable and may also be used for a wide variety of tasks outside of the workshop such as cleaning up water or, in the case of units with detachable blowers, blowing leaves or cleaning porches and sidewalks. A good quality shop vac will flow around 150 to 200 CFM with no restrictions which is 20% to 30% more flow than most dust extractor models. The trade is about 25% lower max static vacuum pressure. In most normal use cases a shop vac will outflow a dust extractor so it is superior from a flow standpoint. Some exceptions might be when attached to tools with very small outlet diameters such as palm sanders. In any case, the flow will provide excellent dust collection for almost any tool if the tool dust ports are modified properly.

Click the following link to see how to achieve effective dust collection from a table saw with only a shop vac. In future articles I'll show you how to achieve effective dust collection from any tool in your shop with only a shop vac. I got rid of my dust collector years ago to save space and to avoid having to install very expensive and intrusive ducting. I maintain better air quality inside my shop than the air outside the shop using simple shop vac systems combined with the Shop Hacks Ultimate DIY Air Filtration System. The graph below shows how much better it is to collect dust at the source than to wait and try to filter it out after it escapes.

1. They are the cheapest option available. Quality new shop vacs cost $100 to $150. You can easily find a good used shop vac for under $30. Add a high quality filter for about $20 and you have an effective way to control dust in your shop for $50 total.

2. They are offered in a very wide range of sizes and flow rates.

3. Cordless models are available

4. The largest shop vacs flow more cfm than dust extractors

5. Shop vacs can be used to clean up anything including dust, rocks, water, metal. Pretty much anything that is not hot and that will fit through the hose can be vacuumed up using a shop vac with no worries of damage.

Accessories

- Bag filters - low cost for most brands, great as a second level of filtration after a cyclone separator. Dust collectors sometimes use bags as the only means to filter the air. In most cases, bag filters are less effective than cartridge filters for dust collection systems.

- Cartridge filters - high filtration efficiency available up to 99.97% for particles over 0.3 microns. More surface area than bags means less flow loss over time.

- Cyclone separators - They use centrifugal forces to spin the dust from the air stream. They remove 95-100% of dust from the air stream. This makes your bags and filters last 20x -100x longer between cleaning/replacement. Available for shop vacs and dust collectors. Match the cyclone to the flow rate it will be used for.

- Hoses, ducting, fittings and attachments - Most people use one vac or dust collector and move a flex hose from tool to tool. Some install permanent ducting in their shops to save time. Ducting sizes, types and prices vary drastically. Shop vac systems work best with 2" to 3" ID hoses and ducting. 600 cfm dust collectors require a minimum of 4" ID but perform better with 5" or 6" hoses and ducting. Dust collectors over 600 cfm need a minimum of 6" ID hoses and ducting when maximum flow rate is needed.

- Motor speed controller - This allows you to control the speed of the vac motor. Running a shop vac at reduced speed makes it significantly quieter while allowing enough flow to accomplish most operations. It will also draw less power at lower speed settings.

- Automatic vacuum switch - When you turn a tool on that is plugged into an automatic vacuum switch, the vacuum, which is also plugged into the switch, automatically starts. When you turn the tool off, the vacuum continues to run for a few more seconds then turns itself off.

Shop vacs are very popular option because they are inexpensive, portable and may also be used for a wide variety of tasks outside of the workshop such as cleaning up water or, in the case of units with detachable blowers, blowing leaves or cleaning porches and sidewalks. A good quality shop vac will flow around 150 to 200 CFM with no restrictions which is 20% to 30% more flow than most dust extractor models. The trade is about 25% lower max static vacuum pressure. In most normal use cases a shop vac will outflow a dust extractor so it is superior from a flow standpoint. Some exceptions might be when attached to tools with very small outlet diameters such as palm sanders. In any case, the flow will provide excellent dust collection for almost any tool if the tool dust ports are modified properly.

Click the following link to see how to achieve effective dust collection from a table saw with only a shop vac. In future articles I'll show you how to achieve effective dust collection from any tool in your shop with only a shop vac. I got rid of my dust collector years ago to save space and to avoid having to install very expensive and intrusive ducting. I maintain better air quality inside my shop than the air outside the shop using simple shop vac systems combined with the Shop Hacks Ultimate DIY Air Filtration System. The graph below shows how much better it is to collect dust at the source than to wait and try to filter it out after it escapes.

Dust Extractors

Initially cost about 3x to 6x as much as shop vacs and replacement filters are 2x to 4x as much as high grade shop vac filters. They sometimes use higher end filters and therefore may provide higher efficiency filtration for very fine particles. However, near HEPA level filters are available for many name brand shop vacs now so dust extractors don't always provide a filtration efficiency advantage. Their primary advantage is related to the quiet operation and extra features included.

Unique Benefits Dust Extractors Offer

1. Motor speed control. You can add a motor speed controller to any shop vac for about $25.

2. Most are significantly quieter than shop vacs.

3. Some dust extractors allow stacking accessories on top of the unit which gives them greater utility.

4. Many dust extractors include an automated power port that a tool plugs into. When you turn the tool on, the vacuum automatically starts. When you turn the tool off, the vacuum continues to run for a few more seconds then turns itself off. You can add an automatic vacuum switch to any shop vac for about $30

These 4 benefits are really the only reasons to buy an expensive dust extractor over a quality shop vac system. Several shop vac manufacturers now incorporate noise suppression technology in their vacs so even with less expensive shop vacs you can achieve relatively quiet operation although they are still louder than most dust extractors. As noted, you can add speed control and automatic vacuum switches to shop vacs which makes them attractive alternatives to dust extractors.

Is it worth it to pay the extra money for a dust extractor vs a shop vac? That is a question each person must answer for themselves. It depends on how much you value the 4 unique benefits that dust extractors offer.

One of the least expensive, quiet dust extractors is the Fein Turbo 1 vacuum . At around $250 it offers all of the benefits of a dust extra without the extra cost.

Accessories

1. Motor speed control. You can add a motor speed controller to any shop vac for about $25.

2. Most are significantly quieter than shop vacs.

3. Some dust extractors allow stacking accessories on top of the unit which gives them greater utility.

4. Many dust extractors include an automated power port that a tool plugs into. When you turn the tool on, the vacuum automatically starts. When you turn the tool off, the vacuum continues to run for a few more seconds then turns itself off. You can add an automatic vacuum switch to any shop vac for about $30

These 4 benefits are really the only reasons to buy an expensive dust extractor over a quality shop vac system. Several shop vac manufacturers now incorporate noise suppression technology in their vacs so even with less expensive shop vacs you can achieve relatively quiet operation although they are still louder than most dust extractors. As noted, you can add speed control and automatic vacuum switches to shop vacs which makes them attractive alternatives to dust extractors.

Is it worth it to pay the extra money for a dust extractor vs a shop vac? That is a question each person must answer for themselves. It depends on how much you value the 4 unique benefits that dust extractors offer.

One of the least expensive, quiet dust extractors is the Fein Turbo 1 vacuum . At around $250 it offers all of the benefits of a dust extra without the extra cost.

Accessories

- Bag filters - low cost for most brands, great as a second level of filtration after a cyclone separator. Dust collectors sometimes use bags as the only means to filter the air. In most cases, bag filters are less effective than cartridge filters for dust collection systems.

- Cartridge filters - high filtration efficiency available up to 99.97% for particles over 0.3 microns. More surface area than bags means less flow loss over time.

- Cyclone separators - They use centrifugal forces to spin the dust from the air stream. They remove 95-100% of dust from the air stream. This makes your bags and filters last 20x -100x longer between cleaning/replacement. Available for shop vacs and dust collectors. Match the cyclone to the flow rate it will be used for.

- Hoses, ducting, fittings and attachments - Most people use one vac or dust collector and move a flex hose from tool to tool. Some install permanent ducting in their shops to save time. Ducting sizes, types and prices vary drastically. Shop vac systems work best with 2" to 3" ID hoses and ducting. 600 cfm dust collectors require a minimum of 4" ID but perform better with 5" or 6" hoses and ducting. Dust collectors over 600 cfm need a minimum of 6" ID hoses and ducting when maximum flow rate is needed.

Dust Collectors

Unique Benefits Dust Collectors Offer

1. They last 10x longer than shop vacs and dust extractors. Most dust collectors use heavy duty induction motors that last over 6,000 hours compared to the brushed motors in shop vacs which typically last closer to 600 hours. For shops that run dust collection 8 hours per day 250 days per year (2,000 hours/yr) , a dust collector makes sense from an economical perspective. Most hobbyists use a shop vac for less than 1 hour per week which means they can last as long as 10 to 15 years so the extra expense of a fully ducted dust collector system doesn't make sense in most cases.

2. They produce 3x to 15x more air flow than shop vacs or dust extractors. This high flow rate is essential for effective dust collection if you don't modify your stock tool dust ports to make them effective at lower flow rates.

3. In general they are quieter than most shop vacs. Shop vac impellers turn at around 25,000 rpms which creates a high frequency whine. Dust collectors spin at closer to 3500 rpms which produces a much lower pitched noise that isn't as annoying.

Accessories

1. They last 10x longer than shop vacs and dust extractors. Most dust collectors use heavy duty induction motors that last over 6,000 hours compared to the brushed motors in shop vacs which typically last closer to 600 hours. For shops that run dust collection 8 hours per day 250 days per year (2,000 hours/yr) , a dust collector makes sense from an economical perspective. Most hobbyists use a shop vac for less than 1 hour per week which means they can last as long as 10 to 15 years so the extra expense of a fully ducted dust collector system doesn't make sense in most cases.

2. They produce 3x to 15x more air flow than shop vacs or dust extractors. This high flow rate is essential for effective dust collection if you don't modify your stock tool dust ports to make them effective at lower flow rates.

3. In general they are quieter than most shop vacs. Shop vac impellers turn at around 25,000 rpms which creates a high frequency whine. Dust collectors spin at closer to 3500 rpms which produces a much lower pitched noise that isn't as annoying.

Accessories

- Bag filters - Most dust collectors come with bags as the only means to filter the air. In most cases, bag filters are less effective than cartridge filters in terms of flow rate and filtration efficiency for dust collection systems. Also, many dust collectors come with bags that pass most of the smallest and most dangerous particles that penetrate the full extents of your lungs and get into your bloodstream. Make sure your bag is rated for 1 micron particles or smaller. Most bags will not be effective for particles this small because they create too much back pressure due to insufficient filter area.

- Cartridge filters - high filtration efficiency available up to 99.97% for particles over 0.3 microns. Cartridge filters offer more surface area than bags means less flow loss over time. Oneida and Wynn Environmental sell quality cartridge filters in sizes that fit most dust collectors.

- Cyclone separators - Cyclones use centrifugal force to spin the dust from the air stream. They remove 95-100% of dust from the air stream. This makes your bags and filters last 20x -100x longer between cleaning/replacement. Dust collector cyclones are typically 10x larger than shop vac cyclone separators and require a lot of space in your shop. It is not uncommon for a cyclone for a 5hp dust collector to require over 8' of ceiling height to fit. However, the time and cost they save over the long run is justified.

- Hoses, ducting, fittings and attachments - Most people use one vac or dust collector and move a flex hose from tool to tool. Some install permanent ducting in their shops to save time. Ducting sizes, types and prices vary drastically. 600 cfm dust collectors require a minimum of 4" ID but perform much better with 5" or 6" hoses and ducting. Dust collectors over 600 cfm need a minimum of 6" ID hoses and ducting when maximum flow rate is needed. To run ducting, fittings and hoses for dust collectors in your shop you should plan to spend a minimum of $500. Ducting and fittings costs can easily exceed $10,000 for larger shops using higher flow dust collectors.

Summary

In essence, shop vacs and dust extractors are very similar. They both use brushed motors. They both use very similar impeller designs. They have similar flow rates and maximum vacuum pressures. The main difference between the two are illustrated in the following chart:

In essence, shop vacs and dust extractors are very similar. They both use brushed motors. They both use very similar impeller designs. They have similar flow rates and maximum vacuum pressures. The main difference between the two are illustrated in the following chart:

Affiliate links are used on this page. As an Amazon Associate I earn from qualifying purchases

Related articles:

NEVER Have to Clean Your Shop Vac Filter Again

Dust Deputy vs. Dustopper Cyclone Shootout

The Highest Flow, Highest Collection Efficiency Shop Vac Cyclone Dust Collection System Available

Air Filtration Options

Back to the Dust Collection and Air Filtration Menu

Affiliate links are used on this page. As an Amazon Associate I earn from qualifying purchases. Shop Hacks exists to help you Build YOUR Space!

NEVER Have to Clean Your Shop Vac Filter Again

Dust Deputy vs. Dustopper Cyclone Shootout

The Highest Flow, Highest Collection Efficiency Shop Vac Cyclone Dust Collection System Available

Air Filtration Options

Back to the Dust Collection and Air Filtration Menu

Affiliate links are used on this page. As an Amazon Associate I earn from qualifying purchases. Shop Hacks exists to help you Build YOUR Space!