Workshop Air Filtration Systems - Which one works best?

Would you like to reduce or eliminate that fine layer of dust that settles on everything in your shop at the end of every day?

Shop Hacks tested 13 different commercial and DIY air filtration system setups to determine which one offers the most air cleaning power for the buck. In this article I'll show you which air filtration systems cleaned the air the fastest and how much each one costs. Originally this was a multi part series all about air filtration systems. The testing culminated in the design a low cost, high performance air filtration system design that you can make in less than a day and that cleans the air 3x faster than a $500 Powermatic PM1200 air filtration system.

Shop Hacks tested 13 different commercial and DIY air filtration system setups to determine which one offers the most air cleaning power for the buck. In this article I'll show you which air filtration systems cleaned the air the fastest and how much each one costs. Originally this was a multi part series all about air filtration systems. The testing culminated in the design a low cost, high performance air filtration system design that you can make in less than a day and that cleans the air 3x faster than a $500 Powermatic PM1200 air filtration system.

Click the link below to download the summary of the test results

| shop_hacks_air_filtration_system_shootout_test_results.pdf |

Air Filtration System Shootout Summary of Results:

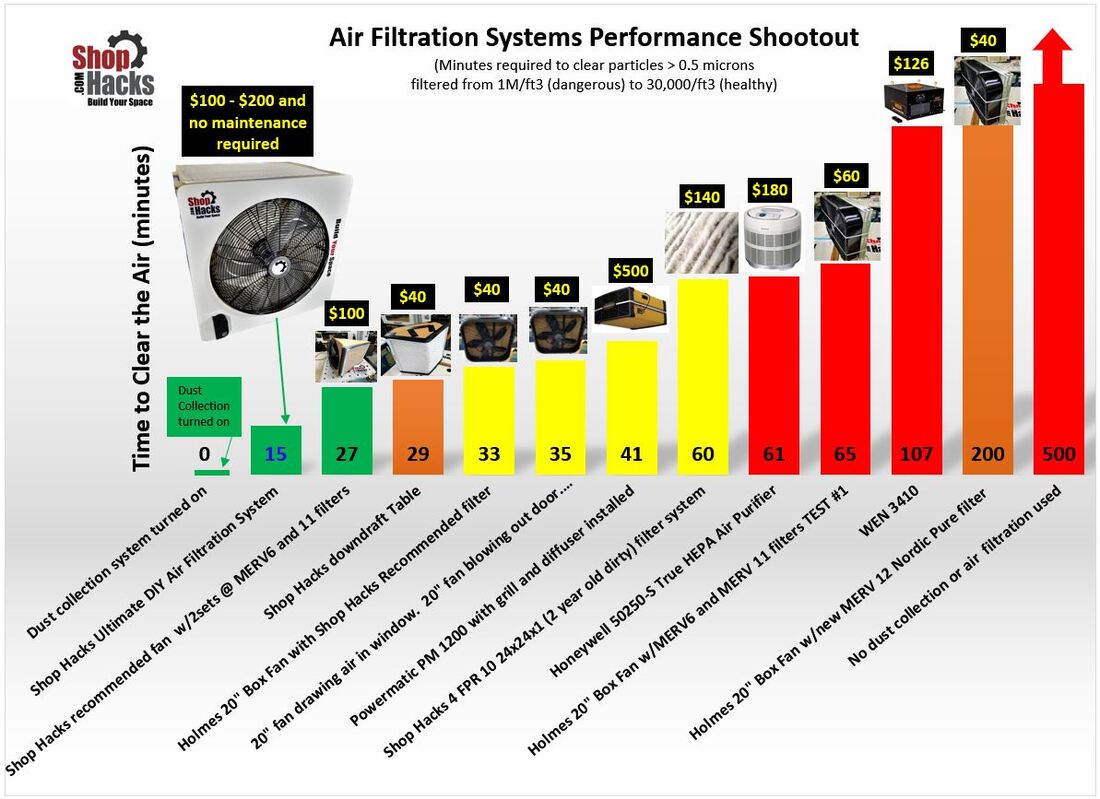

The following chart summarizes the cost and performance test results. Each bar represents how long the system took to clean the air to a healthy level after cutting MDF and melamine on a table saw. More detailed information is presented throughout this article.

The following chart summarizes the cost and performance test results. Each bar represents how long the system took to clean the air to a healthy level after cutting MDF and melamine on a table saw. More detailed information is presented throughout this article.

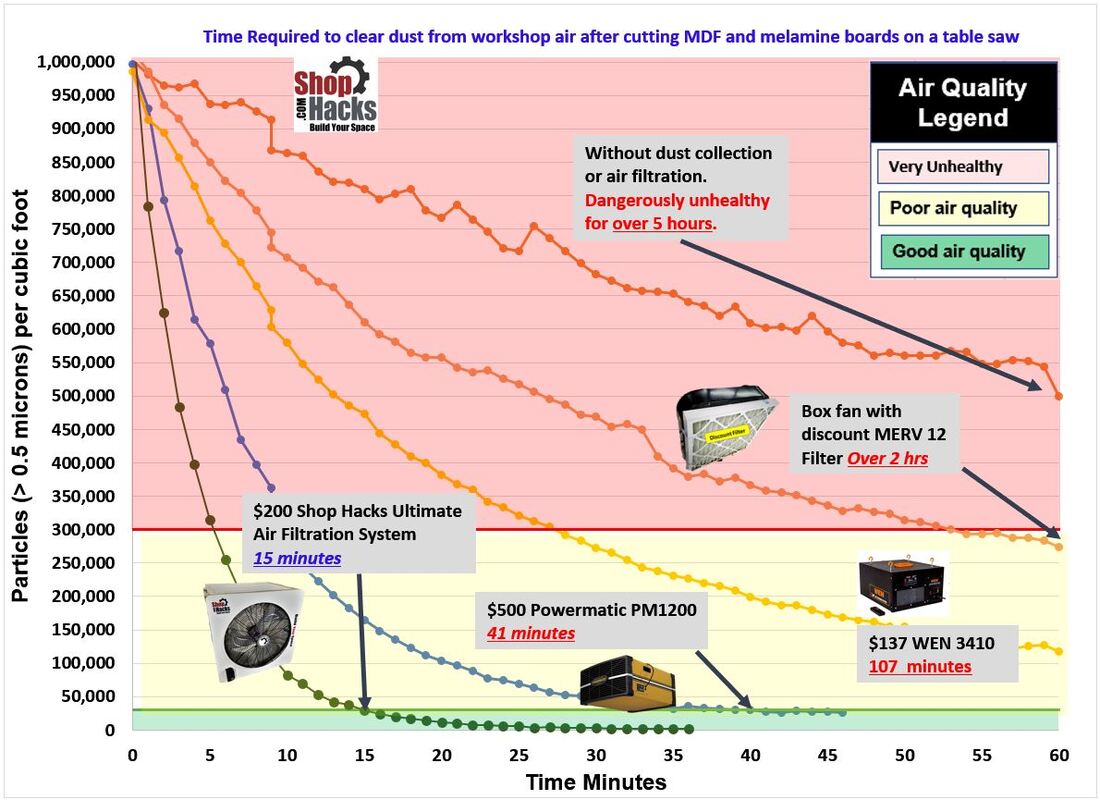

The following graph shows the raw laser particle counter data plotted for the most popular systems. For clarity, not all systems are shown.

Systems Tested and Time Required To Filter The Air (worst to best)

#13 5+ hours. BASELINE - no dust collection and no air filtration.

#12 2+ hours. 20" box fan with a 20x20x2 off brand "MERV 12" filter (I personally NEVER trust a filter other than 3M or Honeywell unless I could test it using a laser particle counter). I suggest that you use an air quality meter to evaluate the performance of any filter system you use in your workshop and decide for yourself.

#11 2+ hours. WEN 3410 Air Filtration System (squirrel cage blower, bag filter, prefilter)

#10 65 minutes. 20" box fan with 3M MERV 6 and MERV 11 filters on the inlet

#9 61 minutes. Honeywell 50250-S True HEPA Air Purifier (squirrel cage blower, HEPA filter, mesh prefilter)

#8 60 minutes. Shop Hacks Prototype with 4@2-year-old dust caked filters - (2000 CFM axial fan with four 24x24x1 Honeywell FPR10 - MERV 13- filters)

#7 41 minutes. Powermatic PM1200 air filtration system (squirrel cage blower, bag filter, prefilter)

#6 35 minutes. 20" box fan drawing fresh air in window and 20" box fan blowing fresh air out the door (no filters)

#5 33 minutes. 20" box fan with 3M 20x25x1 off brand "MERV 13" filter

#4 29 minutes. Shop Hacks downdraft table - (1200 CFM squirrel cage blower with two 20x25x1 and one 20x25x4 inlet filters and one 14x24x1 outlet filter. Inlet filters: 1" MERV 6?, 4" MERV 12, 1" MERV 13, 1" MERV 8?)

#3 27 minutes. 2000 CFM axial fan with two sets of 3M MERV 6 and MERV 11 filters

#2 15 minutes. Shop Hacks Ultimate DIY Air Filtration System - 2000 (CFM axial fan and five 20x25x1 MERV 13 filters)

#1 0 minutes. Shop Hacks dust collection system, no air filtration

#13 5+ hours. BASELINE - no dust collection and no air filtration.

#12 2+ hours. 20" box fan with a 20x20x2 off brand "MERV 12" filter (I personally NEVER trust a filter other than 3M or Honeywell unless I could test it using a laser particle counter). I suggest that you use an air quality meter to evaluate the performance of any filter system you use in your workshop and decide for yourself.

#11 2+ hours. WEN 3410 Air Filtration System (squirrel cage blower, bag filter, prefilter)

#10 65 minutes. 20" box fan with 3M MERV 6 and MERV 11 filters on the inlet

#9 61 minutes. Honeywell 50250-S True HEPA Air Purifier (squirrel cage blower, HEPA filter, mesh prefilter)

#8 60 minutes. Shop Hacks Prototype with 4@2-year-old dust caked filters - (2000 CFM axial fan with four 24x24x1 Honeywell FPR10 - MERV 13- filters)

#7 41 minutes. Powermatic PM1200 air filtration system (squirrel cage blower, bag filter, prefilter)

#6 35 minutes. 20" box fan drawing fresh air in window and 20" box fan blowing fresh air out the door (no filters)

#5 33 minutes. 20" box fan with 3M 20x25x1 off brand "MERV 13" filter

#4 29 minutes. Shop Hacks downdraft table - (1200 CFM squirrel cage blower with two 20x25x1 and one 20x25x4 inlet filters and one 14x24x1 outlet filter. Inlet filters: 1" MERV 6?, 4" MERV 12, 1" MERV 13, 1" MERV 8?)

#3 27 minutes. 2000 CFM axial fan with two sets of 3M MERV 6 and MERV 11 filters

#2 15 minutes. Shop Hacks Ultimate DIY Air Filtration System - 2000 (CFM axial fan and five 20x25x1 MERV 13 filters)

#1 0 minutes. Shop Hacks dust collection system, no air filtration

Lessons learned -

1. Even a powerful air filtration system can not maintain a healthy air quality in your shop unless you have effective dust collection in place. Click this link to learn how to capture 99% of the dust from your table saw (or any tool) with a shop vac or a small dust collector.

2. I TRUST 3M AND HONEYWELL FILTERS. EVEN THOUGH ALL FILTERS CATCH VISIBLE DUST, I BELIEVE THAT SOME ARE ALMOST USELESS AND OFFER LITTLE TO NO PROTECTION! I can't tell you how many times I've seen someone showing dust on the filter attached to a box fan thinking that it is protecting them. The dust you can see doesn't penetrate deep into your lungs and therefore isn't as dangerous as the very fine dust that penetrates deep and gets into your bloodstream. In my opinion, cheap filters and some off brand filters capture very little of the smallest and most dangerous particles under 5 microns.

3. Always use as much filter area as possible! Air resistance through a filter drops as the square of the filter area. That means if you double the area you cut resistance by 4x. The following shows you how important a very large filter area is...

2x filter area = 1/4th as much flow resistance

4x filter area = 1/16th as much flow resistance

5x filter area = 1/25th as much flow resistance

The Shop Hacks Ultimate DIY Air Filtration System has about 10x as much filter area as the prefilter of most air filtration systems. This means that if has 1/100th as much flow resistance at the same flow rate. That allows the use of an axial fan instead of a squirrel cage blower. The axial fan I use produces about 1/10th as much pressure drop as a squirrel cage blower but since the system has 1/100th as much flow resistance it will loose much less flow even when the filters are dirty. That means you may never have to clean the Shop Hacks system filters since they will still flow a significant amount of air even when they have a dust cake.

4. Some designs are better with a squirrel cage blower and some are better with an axial fan. If you only have room for one or two filters then use squirrel cage blower so it maintains flow even when the filter gets a little dirty. If you can use 4 or 5 filters then you can use an axial fan and get twice as much flow for less than half as much power.

5. Dirty filters remain 80% efficient for particles > 0.5 microns. The filtration efficiency for particles > 0.5 microns drops some as the filter gets dirty but even after two years running 24/7 and caked with dust, the Shop Hacks prototype system still filtered at 80% efficiency.

6. Box fan filtration systems can be surprisingly effective if you use the right filter(s) and keep the filter clean. The $40 20" box fan using a 3M 20x25x1" MERV 13 was more effective (with a clean filter) than a $500 Powermatic PM1200 air filtration system. The Powermatic would lose less performance over time since the squirrel cage blower can move more air through a dirty filter but if you keep the filter on the box fan system clean then it should perform very well over time.

7. Filtration performance isn't affected very much by orientation or location. I ran one test using a recirculation fan in the room and one test without. Both tests performed exactly the same. Very fine dust acts more like a gas than a particle so it disperses pretty evenly throughout the room, similar to the way paint fumes do. This means that you can put your filtration system in the middle of the room, on the ceiling, on the floor, under a bench, or wherever is most convenient and it will perform about the same.

8. From a temperature standpoint, orientation and location may matter. The air 8' up is typically around 5F warmer than the air at the floor. If your air filtration system is drawing air from up high it will likely blow hotter air out than you feel closer to the floor. In the summer it's best to draw air from near the floor and in the winter it's better to draw air from as high as possible.

9. The Shop Hacks Ultimate DIY Air Filtration System offers the most flow, the highest filtration efficiency, the least loss of flow as the filters get dirty, uses the lowest amount of power and is the quietest high performance air filtration system available for less than $1,000 and it offers the same remote power on/off/timer functions as the name brand systems.

I tested all of the other systems, learned the inherent strengths and weaknesses of each, then designed the Shop Hacks Ultimate DIY Air Filtration System to incorporate all of the strengths without any of the weaknesses, and at a price to performance ratio that surpasses anything else on the market by a very wide margin. Some of the benefits are listed below.

1. Even a powerful air filtration system can not maintain a healthy air quality in your shop unless you have effective dust collection in place. Click this link to learn how to capture 99% of the dust from your table saw (or any tool) with a shop vac or a small dust collector.

2. I TRUST 3M AND HONEYWELL FILTERS. EVEN THOUGH ALL FILTERS CATCH VISIBLE DUST, I BELIEVE THAT SOME ARE ALMOST USELESS AND OFFER LITTLE TO NO PROTECTION! I can't tell you how many times I've seen someone showing dust on the filter attached to a box fan thinking that it is protecting them. The dust you can see doesn't penetrate deep into your lungs and therefore isn't as dangerous as the very fine dust that penetrates deep and gets into your bloodstream. In my opinion, cheap filters and some off brand filters capture very little of the smallest and most dangerous particles under 5 microns.

3. Always use as much filter area as possible! Air resistance through a filter drops as the square of the filter area. That means if you double the area you cut resistance by 4x. The following shows you how important a very large filter area is...

2x filter area = 1/4th as much flow resistance

4x filter area = 1/16th as much flow resistance

5x filter area = 1/25th as much flow resistance

The Shop Hacks Ultimate DIY Air Filtration System has about 10x as much filter area as the prefilter of most air filtration systems. This means that if has 1/100th as much flow resistance at the same flow rate. That allows the use of an axial fan instead of a squirrel cage blower. The axial fan I use produces about 1/10th as much pressure drop as a squirrel cage blower but since the system has 1/100th as much flow resistance it will loose much less flow even when the filters are dirty. That means you may never have to clean the Shop Hacks system filters since they will still flow a significant amount of air even when they have a dust cake.

4. Some designs are better with a squirrel cage blower and some are better with an axial fan. If you only have room for one or two filters then use squirrel cage blower so it maintains flow even when the filter gets a little dirty. If you can use 4 or 5 filters then you can use an axial fan and get twice as much flow for less than half as much power.

5. Dirty filters remain 80% efficient for particles > 0.5 microns. The filtration efficiency for particles > 0.5 microns drops some as the filter gets dirty but even after two years running 24/7 and caked with dust, the Shop Hacks prototype system still filtered at 80% efficiency.

6. Box fan filtration systems can be surprisingly effective if you use the right filter(s) and keep the filter clean. The $40 20" box fan using a 3M 20x25x1" MERV 13 was more effective (with a clean filter) than a $500 Powermatic PM1200 air filtration system. The Powermatic would lose less performance over time since the squirrel cage blower can move more air through a dirty filter but if you keep the filter on the box fan system clean then it should perform very well over time.

7. Filtration performance isn't affected very much by orientation or location. I ran one test using a recirculation fan in the room and one test without. Both tests performed exactly the same. Very fine dust acts more like a gas than a particle so it disperses pretty evenly throughout the room, similar to the way paint fumes do. This means that you can put your filtration system in the middle of the room, on the ceiling, on the floor, under a bench, or wherever is most convenient and it will perform about the same.

8. From a temperature standpoint, orientation and location may matter. The air 8' up is typically around 5F warmer than the air at the floor. If your air filtration system is drawing air from up high it will likely blow hotter air out than you feel closer to the floor. In the summer it's best to draw air from near the floor and in the winter it's better to draw air from as high as possible.

9. The Shop Hacks Ultimate DIY Air Filtration System offers the most flow, the highest filtration efficiency, the least loss of flow as the filters get dirty, uses the lowest amount of power and is the quietest high performance air filtration system available for less than $1,000 and it offers the same remote power on/off/timer functions as the name brand systems.

I tested all of the other systems, learned the inherent strengths and weaknesses of each, then designed the Shop Hacks Ultimate DIY Air Filtration System to incorporate all of the strengths without any of the weaknesses, and at a price to performance ratio that surpasses anything else on the market by a very wide margin. Some of the benefits are listed below.

Test Setup

For each test I cut about 12 feet of ½” MDF and 12 feet of ¾” melamine on a table saw. The blade was elevated 2” above the stock to create even more dust. This raised the dust concentration levels in the shop to over 1,000,000 particles per cubic foot (particles > 0.5 microns). After the cuts were completed and the particle count dropped to 1M particles per cubic foot, an air filtration system was turned on. Particle counts were logged from 1M particles/ft3 (very unhealthy air quality) until they reached 30,000 particles/ft3 ("good" air quality) and the time was noted. My shop is 24x32x8 (around 6,000 cubic feet). If these tests were run in a larger shop the initial concentration would have been lower but it would have taken longer to clear the air. For smaller shops the initial concentration would be higher and it would take less time to reach the "good" air quality level.

The following were tested/noted for each system:

1. Initial cost

2. How long it took each system to bring dust concentrations from 1,000,000 particles per cubic foot (particle > 0.5 microns, extremely unhealthy) to 30,000 particles per square foot (healthy) after cutting

3. Filtration efficiency

4. Power consumption and estimated yearly cost of operation

5. Flow rate and maximum static pressure

6. Noise levels

7. Features

A chart showing all of this information is available in the Air Filtration Shootout Article article. For those who want to dive into the details and learn everything you can about this subject, that article takes a much deeper dive into the testing and results.

Unless otherwise noted, there was no forced air circulation or ventilation in the shop during the tests other than the air filtration systems. During one test I tested with and without a re-circulation fan to see if extra air circulation would affect the efficiency of the air filtration system.

For each test I cut about 12 feet of ½” MDF and 12 feet of ¾” melamine on a table saw. The blade was elevated 2” above the stock to create even more dust. This raised the dust concentration levels in the shop to over 1,000,000 particles per cubic foot (particles > 0.5 microns). After the cuts were completed and the particle count dropped to 1M particles per cubic foot, an air filtration system was turned on. Particle counts were logged from 1M particles/ft3 (very unhealthy air quality) until they reached 30,000 particles/ft3 ("good" air quality) and the time was noted. My shop is 24x32x8 (around 6,000 cubic feet). If these tests were run in a larger shop the initial concentration would have been lower but it would have taken longer to clear the air. For smaller shops the initial concentration would be higher and it would take less time to reach the "good" air quality level.

The following were tested/noted for each system:

1. Initial cost

2. How long it took each system to bring dust concentrations from 1,000,000 particles per cubic foot (particle > 0.5 microns, extremely unhealthy) to 30,000 particles per square foot (healthy) after cutting

3. Filtration efficiency

4. Power consumption and estimated yearly cost of operation

5. Flow rate and maximum static pressure

6. Noise levels

7. Features

A chart showing all of this information is available in the Air Filtration Shootout Article article. For those who want to dive into the details and learn everything you can about this subject, that article takes a much deeper dive into the testing and results.

- The particle counts were measured using a Dylos DC1100 Pro laser particle counter with a computer interface.

- Power consumption was tested using a Kill-A-Watt power meter.

- Air velocity was measured using an anemometer and/or a pitot tube. CFM was calculated using weighted values based on measurement area x measured air velocity.

- Maximum static pressure for each fan or blower was measured by blocking the inlet to the fan or blower and measuring the differential pressure using a digital manometer

Unless otherwise noted, there was no forced air circulation or ventilation in the shop during the tests other than the air filtration systems. During one test I tested with and without a re-circulation fan to see if extra air circulation would affect the efficiency of the air filtration system.

If you want to take a deep dive into all of the testing and results then check out the Air Filtration Shootout Article article. I go into much more detail about the test setups and results if you are interested.

I used everything I learned during the testing to develop the Shop Hacks Ultimate DIY Air Filtration System

I used everything I learned during the testing to develop the Shop Hacks Ultimate DIY Air Filtration System

Next Article: Why Clean Air Matters - in depth review

Back to the Dust Collection and Air Filtration Menu

Affiliate links may be used on this page. As an Amazon Associate I earn from qualifying purchases. Shop Hacks exists to help you Build YOUR Space!

Back to the Dust Collection and Air Filtration Menu

Affiliate links may be used on this page. As an Amazon Associate I earn from qualifying purchases. Shop Hacks exists to help you Build YOUR Space!