Dust Deputy vs. Dustopper Cyclone Shootout

The Ultimate Shop Vac Cyclone Review - using scientific methods

In this article I will compare the Oneida Dust Deputy, the Home Depot D ustopper, and the Dust Sheriff cyclone separator s.

You will learn...

1. Which one flows the most air. More airflow means less time cleaning up.

2. How much dust they remove. Better separation efficiency means less time cleaning and replacing filters.

3. How well each system works for coarse, medium, and fine dust as well as with a large vac vs a small vac.

4. Exactly how the tests were performed.

5. Cost for each system including all accessories needed.

6. Other tips to get the most out of your cyclone separator.

7. Other cyclone models available with links to reviews.

I performed over 40 tests to determine the performance characteristics of each cyclone separator. After performing these tests I developed the Dust Sheriff shop vac cyclone separator which flows more air and catches more dust. If you are interested, you will find very detailed test information and results available at the end of this article.

Why use a cyclone separator with your shop vac?

Without a cyclone separator you will have to clean your shop vac or dust collector filter 5x to 100x more often, depending on the type of dust you collect. If you use your shop vac or dust collector very often, a cyclone separator will quickly pay for itself with the time and money it saves.

You will learn...

1. Which one flows the most air. More airflow means less time cleaning up.

2. How much dust they remove. Better separation efficiency means less time cleaning and replacing filters.

3. How well each system works for coarse, medium, and fine dust as well as with a large vac vs a small vac.

4. Exactly how the tests were performed.

5. Cost for each system including all accessories needed.

6. Other tips to get the most out of your cyclone separator.

7. Other cyclone models available with links to reviews.

I performed over 40 tests to determine the performance characteristics of each cyclone separator. After performing these tests I developed the Dust Sheriff shop vac cyclone separator which flows more air and catches more dust. If you are interested, you will find very detailed test information and results available at the end of this article.

Why use a cyclone separator with your shop vac?

Without a cyclone separator you will have to clean your shop vac or dust collector filter 5x to 100x more often, depending on the type of dust you collect. If you use your shop vac or dust collector very often, a cyclone separator will quickly pay for itself with the time and money it saves.

If you aren't familiar with how cyclone separators work and want to know, check out the All About Cyclone Separators page.

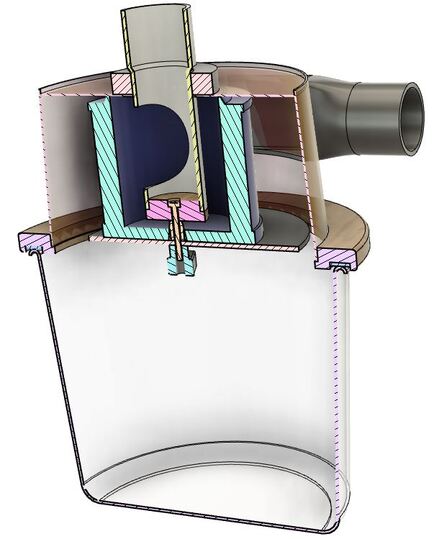

The two most popular shop vac cyclone separators on the market are the Oneida Dust Deputy and the Home Depot Dustopper. The Dustopper is a relatively new entry and is based on Phil Thien's design. The Shop Hacks Dust Sheriff was developed based on lessons learned while testing the other cyclone systems. The Dust Sheriff includes an option to install an INTEGRATED filter which no other shop vac cyclone offers. Unless otherwise noted, flow rate test results in this article are with the filter installed. Separation efficiency test results are without the filter installed.

The two most popular shop vac cyclone separators on the market are the Oneida Dust Deputy and the Home Depot Dustopper. The Dustopper is a relatively new entry and is based on Phil Thien's design. The Shop Hacks Dust Sheriff was developed based on lessons learned while testing the other cyclone systems. The Dust Sheriff includes an option to install an INTEGRATED filter which no other shop vac cyclone offers. Unless otherwise noted, flow rate test results in this article are with the filter installed. Separation efficiency test results are without the filter installed.

The Shop Hacks Dust Sheriff. >$15 in materials (integrated filter is optional)

Overall Test Results: (much more detailed results presented later in the article if you are interested)

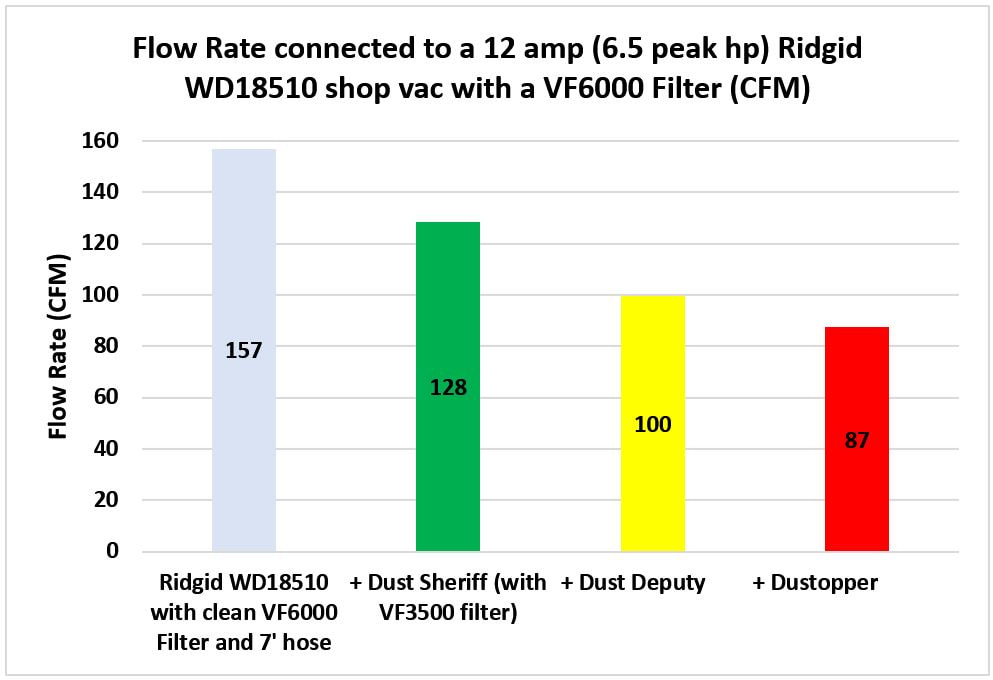

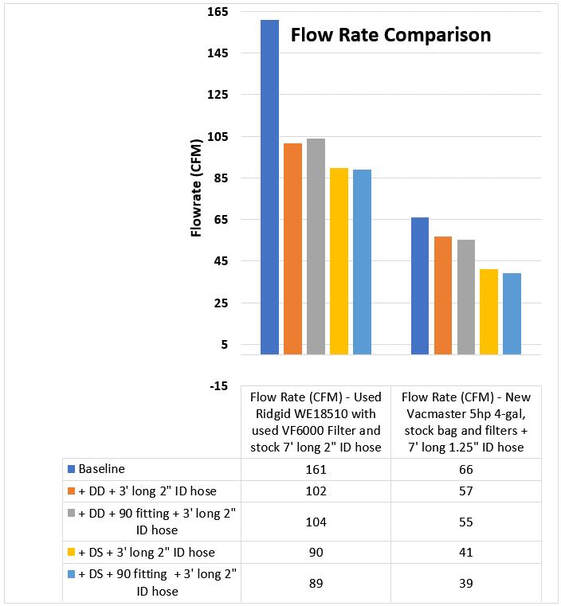

Flow rate comparison - More flow = more time making and less time cleaning

All of the cyclones reduced the vac flow rate. With the large shop vac the Dust Sheriff flowed 32% more air than the Dustopper and 28% more air than the Dust Deputy. More airflow means you collect the dust faster so you spend more time on your projects and less time cleaning.

All of the cyclones reduced the vac flow rate. With the large shop vac the Dust Sheriff flowed 32% more air than the Dustopper and 28% more air than the Dust Deputy. More airflow means you collect the dust faster so you spend more time on your projects and less time cleaning.

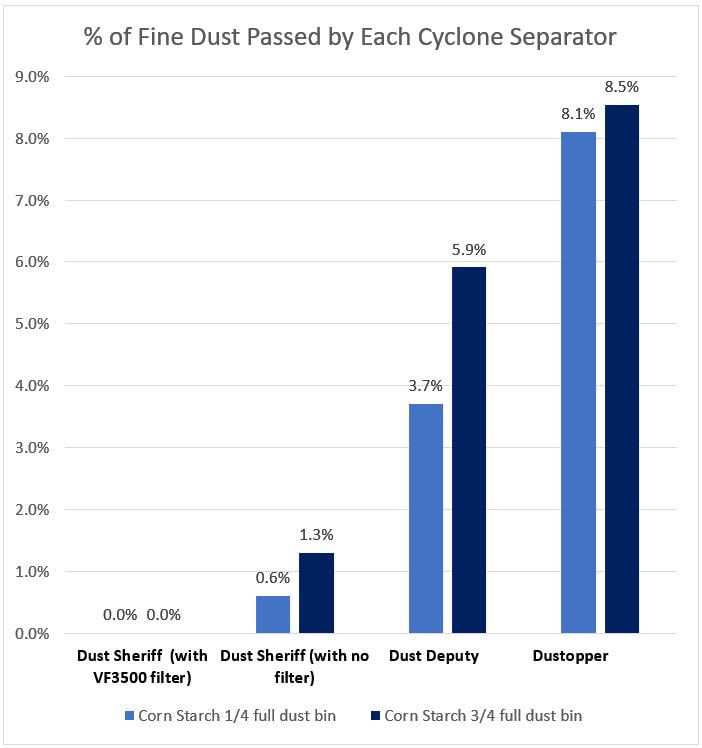

Dust Removal Efficiency: Higher efficiency means less filter cleaning and replacement.

This chart shows how much of two kinds of dust each system passed using the large shop vac. More detailed results including coarse dust and a smaller shop vac testing are included later in the article.

The Dust Deputy passed about 5x more corn starch dust than the Dust Sherriff and the Dustopper passed over 10x more fine dust than the Dust Sheriff. If you collect a lot of fine dust this is significant because the more dust the cyclone separates out the less often you will have to clean your shop vac filter. That means up to 10x longer filter life using the Dust Sheriff.

The Dust Deputy passed about 5x more corn starch dust than the Dust Sherriff and the Dustopper passed over 10x more fine dust than the Dust Sheriff. If you collect a lot of fine dust this is significant because the more dust the cyclone separates out the less often you will have to clean your shop vac filter. That means up to 10x longer filter life using the Dust Sheriff.

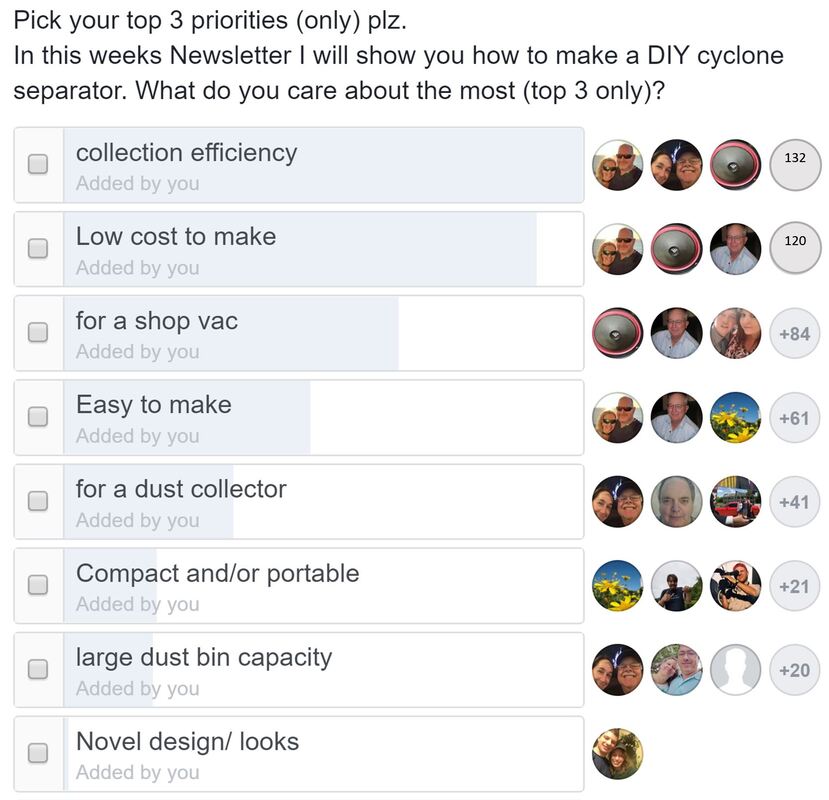

I polled the Shop Hacks Facebook Group to determine what the group most wanted to see in a cyclone separator. Here's what the group asked for...

Detailed Test Protocol and Results for those of you who want to understand all the details:

The following will focus on the most requested areas and in the order preference noted by the poll results. This will help you choose the best shop vac cyclone separator based on the following criteria:

1. Collection efficiency (based on the type of dust you generate and the size shop vac you intend to use)

2. Cost (one of the two systems has significant hidden costs)

3. Other performance considerations (flow rate reduction, attachments, improvements, etc...)

1. Collection efficiency (based on the type of dust you generate and the size shop vac you intend to use)

2. Cost (one of the two systems has significant hidden costs)

3. Other performance considerations (flow rate reduction, attachments, improvements, etc...)

I performed tests including combinations of all of the following variables:

1. High and low flow rate shop vacs. (Ridgid WD18510 16 gal, 6.5 peak hp and the Vacmaster 4 gal, 5 peak hp)

2. Coarse, medium and fine particles which represent the full range of dust produced in most shop.

3. With and without 90 degree connectors (the result of this test was quite surprising!)

1. High and low flow rate shop vacs. (Ridgid WD18510 16 gal, 6.5 peak hp and the Vacmaster 4 gal, 5 peak hp)

2. Coarse, medium and fine particles which represent the full range of dust produced in most shop.

3. With and without 90 degree connectors (the result of this test was quite surprising!)

Why is this review most likely the most comprehensive and most reliable information available?

While I did not perform this test per a formal test standard, as a filter manufacturer might do, I did go a several steps beyond any tests I've seen in blogs or YouTube videos. I want you to trust Shop Hacks as a reliable and thorough source for your workshop related information. We are committed to providing reliable information that takes the guesswork out decisions you make for your workshop. Shop Hacks exists to help you Build YOUR Space!

What did I do differently?

1. Very high accuracy measurements. I built the dust collection fixture shown below to ensure that I captured 99.99% of all of the dust that bypassed the cyclone. I also used a high precision centigram accuracy scale which allowed accurate measurements of fine dust that bypassed the cyclones down to 0.01 grams. When a cyclone passes less than 1% of the dust flowing through it, having centigram accuracy is essential. Even a small 1 gram error would represent a 50% error in some cases.

While I did not perform this test per a formal test standard, as a filter manufacturer might do, I did go a several steps beyond any tests I've seen in blogs or YouTube videos. I want you to trust Shop Hacks as a reliable and thorough source for your workshop related information. We are committed to providing reliable information that takes the guesswork out decisions you make for your workshop. Shop Hacks exists to help you Build YOUR Space!

What did I do differently?

1. Very high accuracy measurements. I built the dust collection fixture shown below to ensure that I captured 99.99% of all of the dust that bypassed the cyclone. I also used a high precision centigram accuracy scale which allowed accurate measurements of fine dust that bypassed the cyclones down to 0.01 grams. When a cyclone passes less than 1% of the dust flowing through it, having centigram accuracy is essential. Even a small 1 gram error would represent a 50% error in some cases.

2. I tested collection efficiency with multiple particle sizes using only virgin dust particles of consistent size for each test. I used virgin table saw dust (coarse), corn meal (medium) and corn starch (very fine).

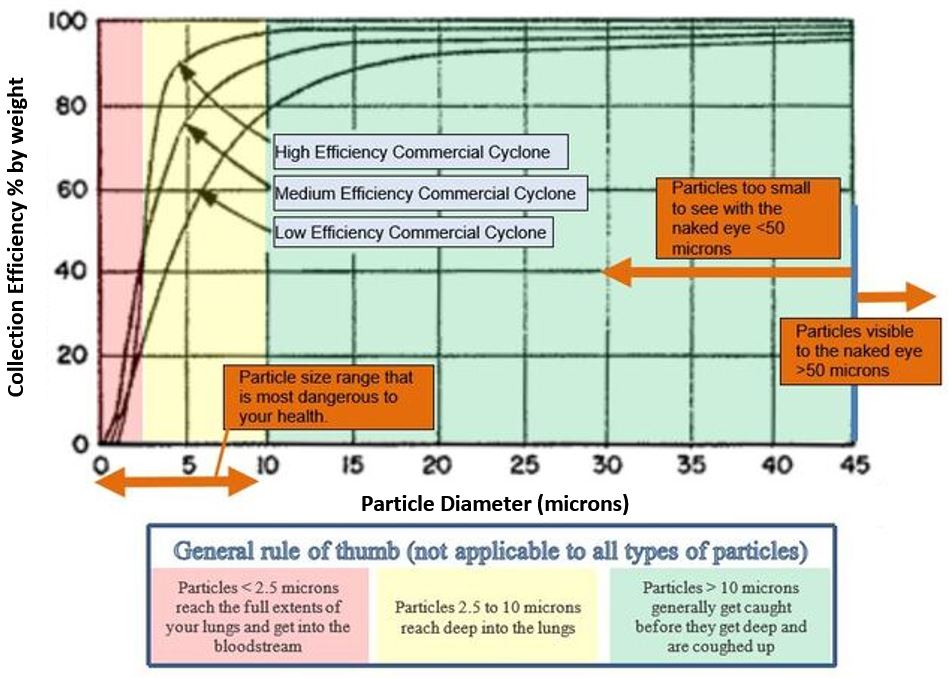

Why is it important to use virgin dust that has not been through a cyclone before? See the figure below which illustrates commercial cyclone collection efficiencies curves. Cyclones pass nearly 100% of the very fine fine dust. Each time dust is sent through a cyclone, the fine dust passes through and the coarse dust is collected. This leads to the dust becoming coarser with each pass and the cyclone collection efficiency appears to increase each time the pile is vacuumed. At some point, with enough passes through the cyclone, the cyclone collection efficiency approaches 100% because there will be no dust remaining that is fine enough to bypass the cyclone. Using virgin dust for every test eliminates this common error.

3. I ran all of the tests two different sized shop vacs to determine the affect flow rate has on collection efficiency. By testing two different size vacs with a wide very different flow rates I was able to accurately determine the collection efficiency for each cyclone at high and low flow rates. Some of the results were surprising.

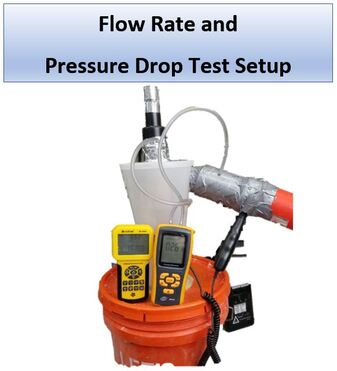

4. I tested flow rate effects and pressure drops across both cyclones in multiple configurations. This will allow you to compare results that are closest to the setup you use to decide which cyclone is best for you.

Test Setup Overview

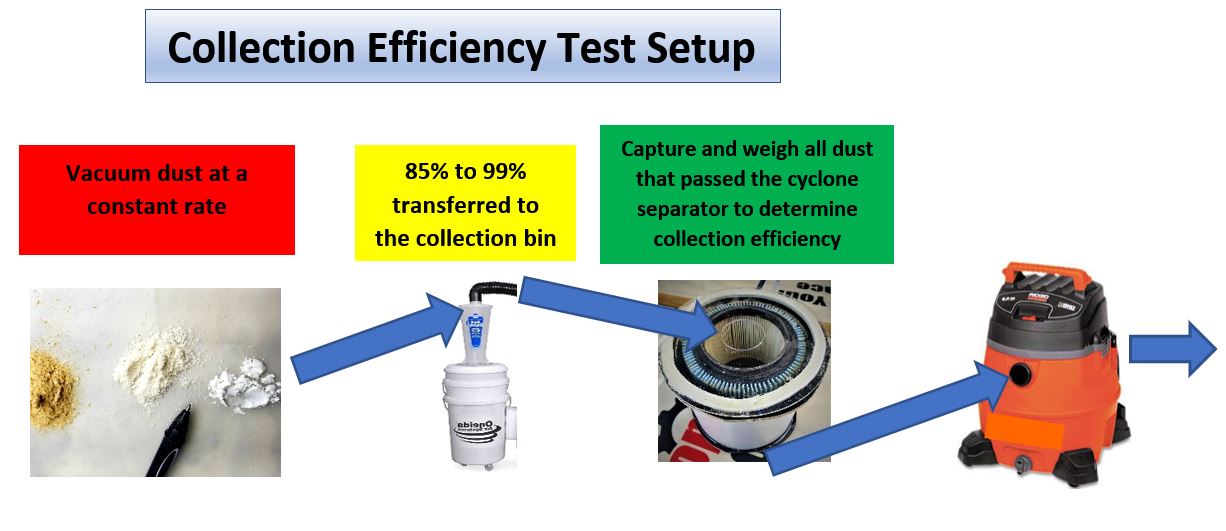

I'll include more details of the setup at the end of the article but the following figure will give you a good idea how the tests were conducted. I weighed the dust was vacuumed for each test as well as the dust that bypassed the cyclone. The ratio of those two was used to calculate the cyclone collection efficiency for each test.

4. I tested flow rate effects and pressure drops across both cyclones in multiple configurations. This will allow you to compare results that are closest to the setup you use to decide which cyclone is best for you.

Test Setup Overview

I'll include more details of the setup at the end of the article but the following figure will give you a good idea how the tests were conducted. I weighed the dust was vacuumed for each test as well as the dust that bypassed the cyclone. The ratio of those two was used to calculate the cyclone collection efficiency for each test.

Equation used: The collection efficiency = [1 - (bypassed weight/vacuumed weight)] x 100.

However, it is more informative to look at efficiency in terms of the percentage of dust that passed the cyclone to the vacuum. Bypassed % = (bypassed weight/vacuumed weight) x 100.

The math is worth looking at for a second. For example, if a cyclone is 99% efficient and another is 98% efficient you may be tempted to believe they are about the same. However the 98% efficient cyclone passes twice as many particles (2%) as the 99% cyclone passes (1%) which means you have to clean your filter twice as often for a 98% efficient cyclone than you do with a 99% efficient cyclone. If we look at it in terms of the % of dust that bypassed the cyclone the results are much more intuitive. One passed 2% and the other passed 1% . In this form it is very easy to recognize that one cyclone is twice as efficient as the other.

This difference gets greatly exaggerated once the efficiency of one cyclone gets close to 100%. I.E. a system using a 98% efficient cyclone requires the filter to be cleaned 20x more often than a system using a 99.9% efficient cyclone. 2% particles passed = 20 x 0.1% particles passed. If one cyclone is 99.9% efficient and the other is 90% efficient then the first one will require filter cleaning 1/100th as often !

However, it is more informative to look at efficiency in terms of the percentage of dust that passed the cyclone to the vacuum. Bypassed % = (bypassed weight/vacuumed weight) x 100.

The math is worth looking at for a second. For example, if a cyclone is 99% efficient and another is 98% efficient you may be tempted to believe they are about the same. However the 98% efficient cyclone passes twice as many particles (2%) as the 99% cyclone passes (1%) which means you have to clean your filter twice as often for a 98% efficient cyclone than you do with a 99% efficient cyclone. If we look at it in terms of the % of dust that bypassed the cyclone the results are much more intuitive. One passed 2% and the other passed 1% . In this form it is very easy to recognize that one cyclone is twice as efficient as the other.

This difference gets greatly exaggerated once the efficiency of one cyclone gets close to 100%. I.E. a system using a 98% efficient cyclone requires the filter to be cleaned 20x more often than a system using a 99.9% efficient cyclone. 2% particles passed = 20 x 0.1% particles passed. If one cyclone is 99.9% efficient and the other is 90% efficient then the first one will require filter cleaning 1/100th as often !

Test Results

Now for the moment you have been waiting for... I'll present the data in charts to make it easy to understand at a glance but I'll include the detailed data at the end of the article if you are interested in analyzing it further.

Collection efficiency

Now for the moment you have been waiting for... I'll present the data in charts to make it easy to understand at a glance but I'll include the detailed data at the end of the article if you are interested in analyzing it further.

Collection efficiency

Important Distinctions

The biggest take away is that the Dust Deputy has a clear advantage when it comes to very fine dust.

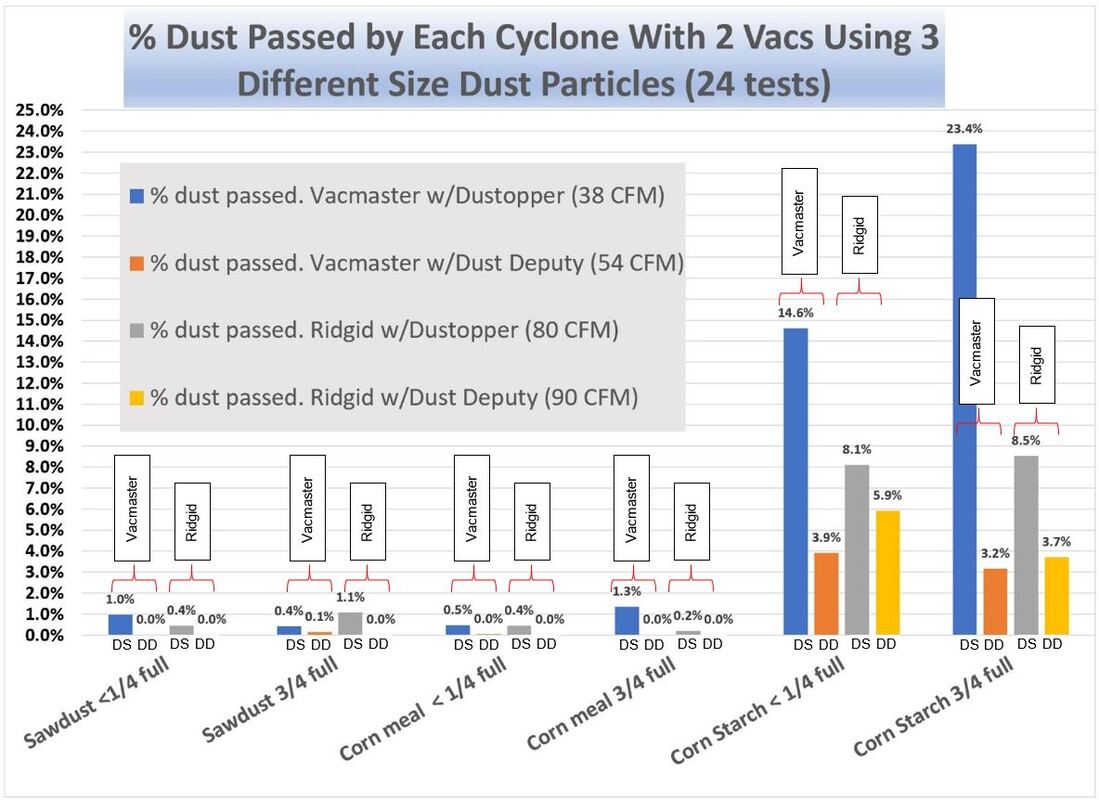

- The Dustopper passed over 7x as much fine dust as the Dust Deputy with the lower flow rate Vacmaster vacuum. It passed almost 2.5x as much dust as the Dust Deputy using the higher flow rate Ridgid vacuum. If you plan to use a cyclone for sanding or other very fine dust then the Dust Deputy is the clear winner.

- the Dust Deputy was 4x to 10x more efficient across the board. Both cyclones were very efficient at removing coarser dust.

- Planer chips or long slivers will jam in slot of the Dustopper causing it to clog up. Planer chips did not clog up the Dust Deputy.

- Both cyclones performed well with table saw dust and coarse dust (corn meal). The Dust Deputy passed almost nothing. The Dustopper passed between 0.4% and 1.1%. Not much but still at least 10x more than the Dust Deputy.

- Neither cyclone seemed to be sensitive to flow rate for either of the coarser dust tests.

- The Dustopper passed significantly more coarse dust when it was 3/4 full with the lower flow rate vac. Otherwise, neither cyclone seemed to be sensitive to whether or not the dust bin was empty or near full.

- For table saw dust and corn meal the systems seemed to perform equally well with the lower flow rate Vacmaster and the higher flow rate Ridgid vac.

- Using the very fine dust starch, the Dustopper passed 2.5x to 7x more dust than the Dust Deputy.

- The Dustopper seems to be more sensitive to low flow rates with fine dust , especially when the bin was 3/4 full, but the Dust Deputy performed well with both vac systems whether empty or near full.

The biggest take away is that the Dust Deputy has a clear advantage when it comes to very fine dust.

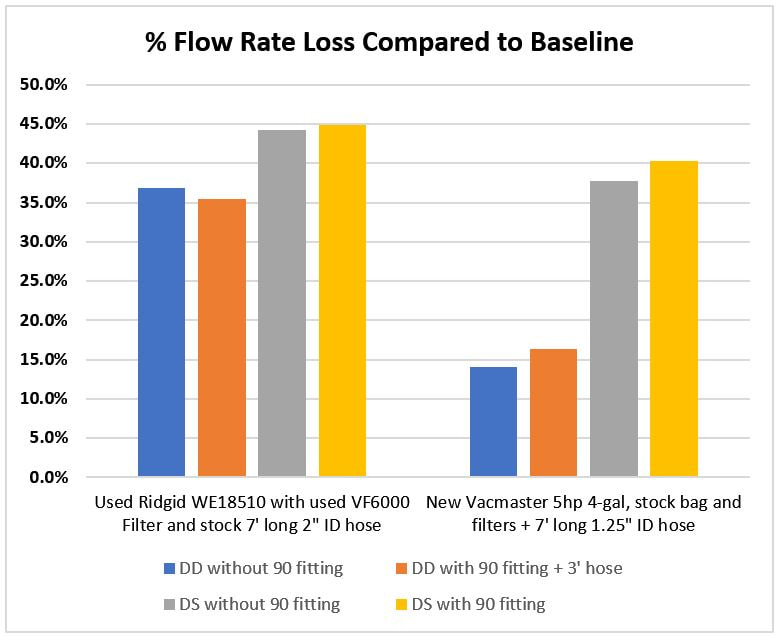

Flow Rate Comparison

I was VERY surprised to see how much both cyclones reduced the flow rates of both vacs. Cyclones use a lot of energy via air friction on the walls as the air spins as well as friction due to the series of direction changes the air encounters along its path. The following chars illustrate how much each vac was affected by connecting each cyclone.

As you see, the Dustopper reduces flow significantly more than the Dust Deputy. The higher flow rate Ridgid vac drops 45% using the Dustopper and 35% using the Dust Deputy. The lower flow rate Vacmaster is affected much less but, as noted earlier, the Dustopper 's separation efficiency drops significantly for fine dust when using the lower flow rate vac.

I also tested each setup with a 90 degree connector attached to the outlet of each cyclone. Typically, 90 degree connections cause a significant reduction in flow rate. However, you will see that there was a negligible change in flow rate with the 90 degree connector attached. My theory is that the spinning of the air exiting the cyclone is slowed down as it makes the 90 degree turn. The air converts that change in kinetic energy into pressure which happens to cancel the losses induced by the 90 degree bend. This is similar to adding flow straighteners to ducts to reduce the pressure losses around bends. It is likely that adding a flow straightener in the outlet of the cyclone and not using the 90 degree fitting would result in a measurably higher flow rate.

As you see, the Dustopper reduces flow significantly more than the Dust Deputy. The higher flow rate Ridgid vac drops 45% using the Dustopper and 35% using the Dust Deputy. The lower flow rate Vacmaster is affected much less but, as noted earlier, the Dustopper 's separation efficiency drops significantly for fine dust when using the lower flow rate vac.

I also tested each setup with a 90 degree connector attached to the outlet of each cyclone. Typically, 90 degree connections cause a significant reduction in flow rate. However, you will see that there was a negligible change in flow rate with the 90 degree connector attached. My theory is that the spinning of the air exiting the cyclone is slowed down as it makes the 90 degree turn. The air converts that change in kinetic energy into pressure which happens to cancel the losses induced by the 90 degree bend. This is similar to adding flow straighteners to ducts to reduce the pressure losses around bends. It is likely that adding a flow straightener in the outlet of the cyclone and not using the 90 degree fitting would result in a measurably higher flow rate.

Cost Comparison

The Home Depot Dustopper, $48.60. (You may be able to get it a little cheaper if you have a local Home Depot)

This includes a 3' hose and a 90 degree fitting to attach it to your vacuum. The only other accessory you need is a 5 gallon bucket. The Dustopper just snaps onto the bucket so no tools or hardware are required.

TOTAL COST: $49

This includes a 3' hose and a 90 degree fitting to attach it to your vacuum. The only other accessory you need is a 5 gallon bucket. The Dustopper just snaps onto the bucket so no tools or hardware are required.

TOTAL COST: $49

I tested the system with no extra seals but i would recommend putting a thin weather seal around the bottom edge that contacts the bucket. That may improve the performance a little by not allowing air to leak through which pulls dusty air up through the cyclone and into your vac.

The Oneida Dust Deputy, $54.95.

This includes the cyclone only. You will still need to buy the following:

$5.00 1 @ 5-gallon bucket or any container that you can attach a sealed lid to. NOTE: shop vacs product up to 3.5 psi vacuum which is 500 lbs/ft2. Any container that can't handle 500 lbs per square foot on any surface will need to be reinforced. I'll show you an easy way to reinforce a 5-gallon bucket in a later section of this article.

$5.00 6 @ 1/4" bolts, washers and nuts

$3.00 Caulk to seal it to a piece of plywood or to a bucket lid

$29.74 1 @ 2.5" (outside diameter) hose to connect to your shop vac. You may be able to find it cheaper but this is the cheapest I

found on Amazon.

TOTAL COST: $103

The Oneida Dust Deputy, $54.95.

This includes the cyclone only. You will still need to buy the following:

$5.00 1 @ 5-gallon bucket or any container that you can attach a sealed lid to. NOTE: shop vacs product up to 3.5 psi vacuum which is 500 lbs/ft2. Any container that can't handle 500 lbs per square foot on any surface will need to be reinforced. I'll show you an easy way to reinforce a 5-gallon bucket in a later section of this article.

$5.00 6 @ 1/4" bolts, washers and nuts

$3.00 Caulk to seal it to a piece of plywood or to a bucket lid

$29.74 1 @ 2.5" (outside diameter) hose to connect to your shop vac. You may be able to find it cheaper but this is the cheapest I

found on Amazon.

TOTAL COST: $103

Or you can just buy the Dust Deputy Deluxe kit for $106.74 which comes with the cyclone, bucket, hardware, hose, fitting and a wheeled dolly.

Other Tips and Considerations

Sound

Several reviews that I watched noted that the Dustopper was noticeably louder than the Dust Deputy. That is true when the hose is not attached to the inlet but I could not hear the cyclone at all over the sound of either vacuum and the Vacmaster is a relatively quiet vacuum.

Leaks and Imploding Buckets

Shop vacs produce enough pressure to implode most 5-gallon buckets. There are a couple ways to prevent this...

1. Simply place one bucket inside of another. This keeps the walls straight which increases their buckling strength. It works for the Dust Deputy, however, it allowed enough deflection of the bucket lid to cause a significant air leak with the Dustopper. Picture the bucket being full of a continuously swirling dust cloud. When air leaks in around the lid seal it flows through that dust cloud carrying dust up and out the cyclone and into the vacuum. You want to prevent air leaks below the clone at all costs.

2. I also tested cutting a ring with a 10 5/8" outside diameter and a 8 5/8" inside diameter out of a piece of 3/4" plywood. You can cut it out with a jigsaw or a bandsaw. If you use a bandsaw just glue the slit back together that is made to cut the inside diameter. Press the ring into the bucket tightly and it will stay in place without glue or fasteners. This method is illustrated below. It works very well without allowing any leaks with either cyclone.

Sound

Several reviews that I watched noted that the Dustopper was noticeably louder than the Dust Deputy. That is true when the hose is not attached to the inlet but I could not hear the cyclone at all over the sound of either vacuum and the Vacmaster is a relatively quiet vacuum.

Leaks and Imploding Buckets

Shop vacs produce enough pressure to implode most 5-gallon buckets. There are a couple ways to prevent this...

1. Simply place one bucket inside of another. This keeps the walls straight which increases their buckling strength. It works for the Dust Deputy, however, it allowed enough deflection of the bucket lid to cause a significant air leak with the Dustopper. Picture the bucket being full of a continuously swirling dust cloud. When air leaks in around the lid seal it flows through that dust cloud carrying dust up and out the cyclone and into the vacuum. You want to prevent air leaks below the clone at all costs.

2. I also tested cutting a ring with a 10 5/8" outside diameter and a 8 5/8" inside diameter out of a piece of 3/4" plywood. You can cut it out with a jigsaw or a bandsaw. If you use a bandsaw just glue the slit back together that is made to cut the inside diameter. Press the ring into the bucket tightly and it will stay in place without glue or fasteners. This method is illustrated below. It works very well without allowing any leaks with either cyclone.

Disclosure: This site uses affiliate links. When you use the links you pay the exact same price but Shop Hacks receives a small commission from anything you purchase from Amazon the following 24 hours. Affiliate commissions help support producing more content like this. Thank you for supporting more great content from Shop Hacks and for helping us help you.

Other Cyclone Separators - Several other cyclone separators are available.

|

$145 CV06 Mini System - This is a very nice cyclone and it may (or may not) offer a very slight collection efficiency compared to the Dust Deputy but the difference would be minimal at best so I didn't buy one for this test.

|

|

$100 Dust Right Dust Separator - This system has an advantage because it holds 10 gallons of dust. However, it doesn't include a baffle to prevent the dust from flying up and exiting the cyclone. I don't believe this system will fare nearly as well in terms of collection efficiency as the two that were tested.

|

|

$25 Chinese Cyclone Separator - Although I didn't test this system I believe it would perform nearly identically to the Dust Deputy. I didn't include it in the test because I don't know if this product is infringing on the Dust Deputy patent or not. If any of you find out that it is infringing, please let me know and I'll remove it from this article.

|

|

$16 Woodstock W2049 Cyclone Separator - I did not include this unit in the test because it would not be very efficient at all for medium to fine dust. However, I would highly recommend this unit as a pre-separator for planer or jointer chips. Send your chips into one of these placed over a large barrel then feed the downstream hose to a standard cyclone separator.

|

Related articles -

NEVER have to clean or change your shop vac filter again!

Build the Ultimate Air Filtration System

Please share and read about more dust collection tips and tricks by joining the Shop Hacks Facebook Group by clicking HERE.

NEVER have to clean or change your shop vac filter again!

Build the Ultimate Air Filtration System

Please share and read about more dust collection tips and tricks by joining the Shop Hacks Facebook Group by clicking HERE.