|

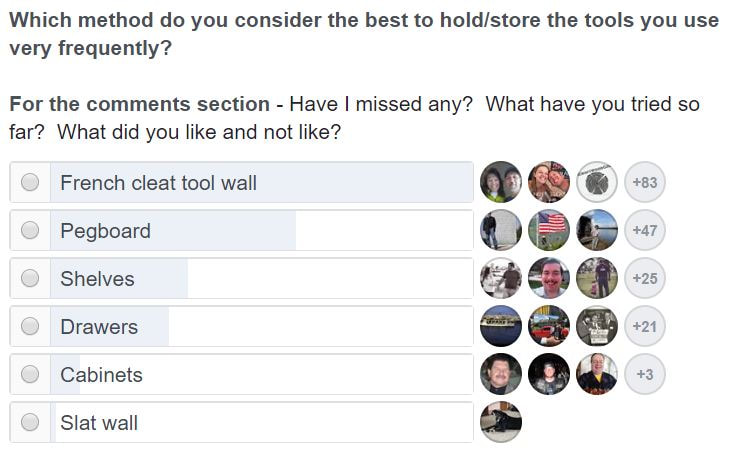

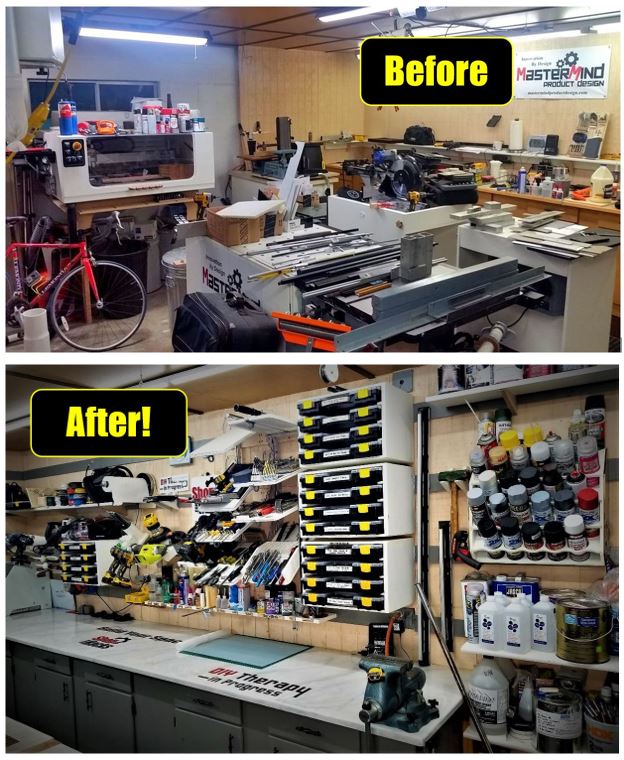

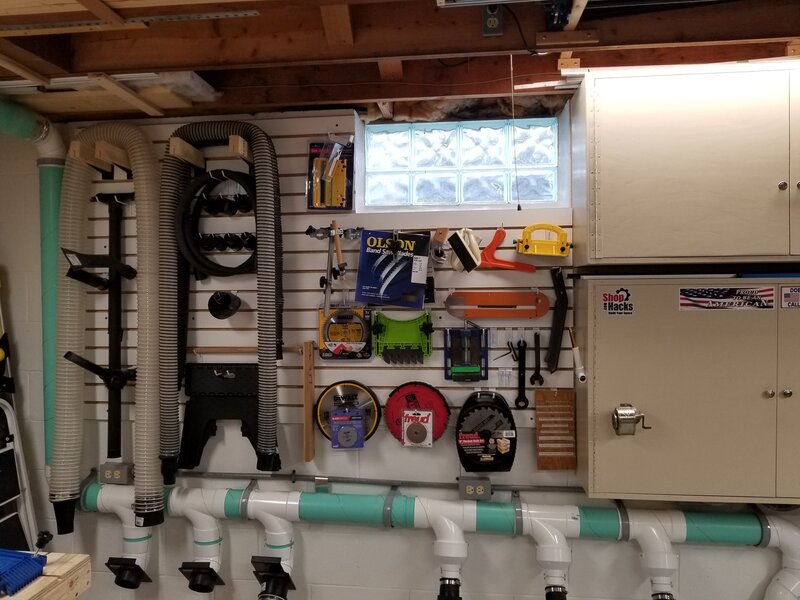

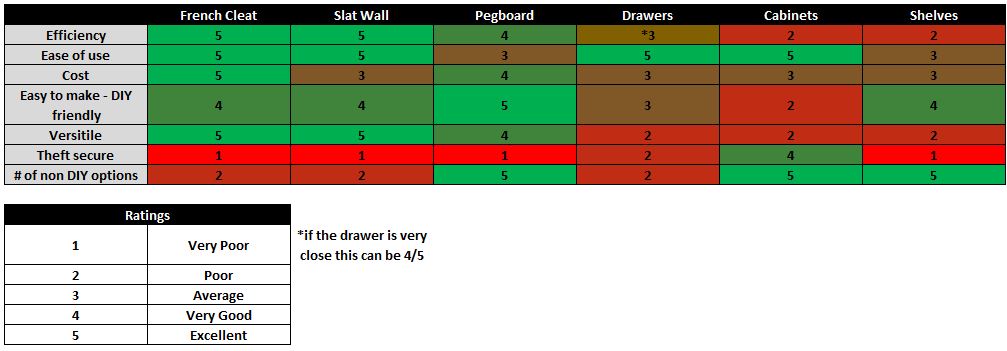

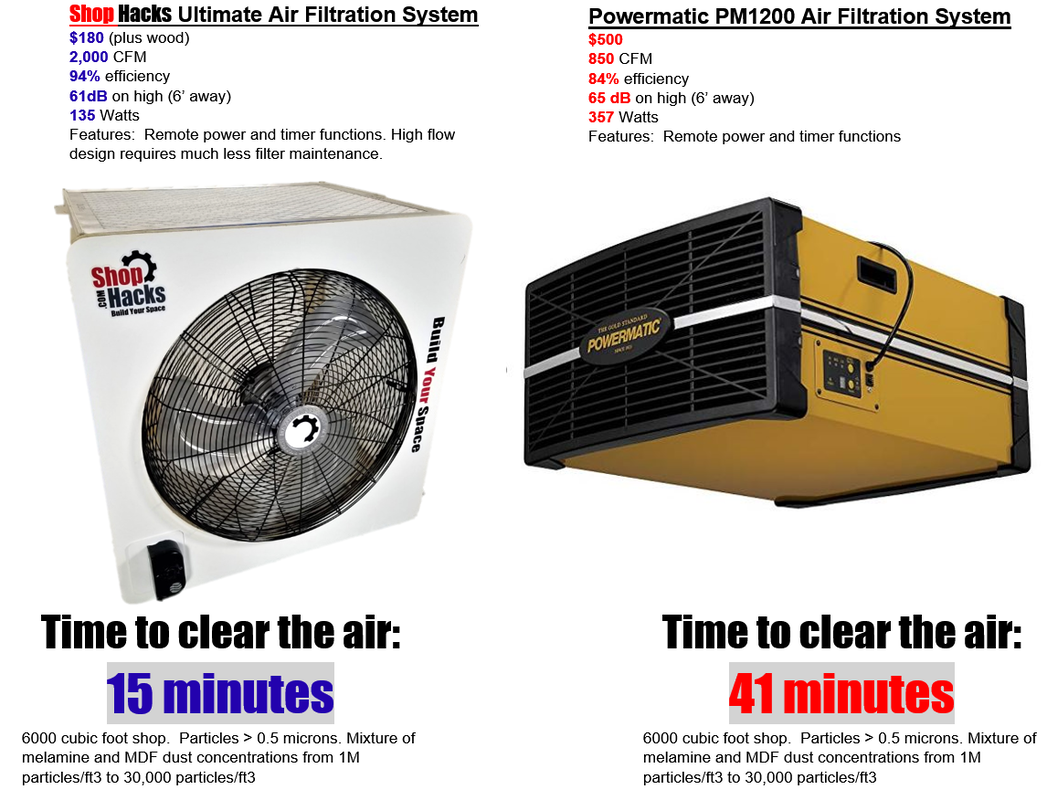

If you would like to receive FREE Shop Hacks like this every Friday at 3:30 Eastern Time... subscribe below... What are your Tool Organizer Options and what might work best in your shop? There are 6 popular types of tool organizers... 7 if you count the pile of tools on your workbench ;-) The following poll was taken in the Shop Hacks Facebook group regarding which system you like the best... I was a little surprised about how much French cleats came out ahead of the rest of the options combined, but I understand why. I'll start with some pictures of each of the popular DIY options then we will get into which ones work best for different situations. At the end of the article I'll show you some of the systems available that you can purchase ready-made. Note... Don't miss next week's article because I will introduce a new organization product that you can use to Build YOUR Space! I'm excited to unveil this innovative but simple and inexpensive Shop Hacks system to all of you! I've improved on an already great system and I'll offer it in a package that takes the hassle out of organizing your workshop! Stay tuned... French Cleats - everything on my tool wall is hanging on a french cleat. I like them because they make it very easy to evolve my tool wall as my workflow and needs change. It is also cheaper and more versatile than any other system. French cleats are really the most versatile option because you can still use all of the other options on a French cleat wall. You can hang cabinets or drawer modules, shelves or even sections of pegboard is you want to. Pictures of Shop Hacks Facebook Group members French Cleat Setups Pegboard is the next most popular option. That's understandable since pegboard is readily available, is relatively cheap, has a wide variety of accessories available and has been around since our grandfathers were working in their shops. The photos below were submitted by members of the Shop Hacks Facebook group. Particularly interesting is Mike Gallucci's blue powder coated metal pegboard workbench design. Great job Mike and thanks for sharing your innovative creations with the group! Slat Walls show up from time to time and they are just as versatile as French cleat walls but they are not nearly as popular for some reason. I believe they are more popular in Europe than in the US. There are a number of very nice accessories available for slat walls. Shelves, Drawers, and Cabinets - I would venture to guess that 99% of us use some combination of these three in our shops. They are ubiquitous and readily available at any big box store in both ready-made and DIY options. They are the default choice if you don't want to spend your energy trying to make your shop as efficient as it can be. However they are horribly inefficient compared to open tool storage and tend to become dumping grounds and hoarding areas where tools and materials go to die. The Shop Hacks Philosophy - Never put frequently used tools or materials in a drawer or cabinet or on a shelf. Use open tool storage within arms reach of each of your work areas and you will spend much less time walking, sorting, opening, closing and moving things around and more time making, fixing and building. For more about how to organize your tools without feeling overwhelmed, check out these articles... tool-organization-how-to-organize-your-tools-without-feeling-overwhelmed.html workshop-organization-how-to-organize-your-materials-and-hardware-without-feeling-overwhelmed.html I ran a quick time study the other day to see how much time I saved by locating my frequently used tools within arms reach compared to where I used to store them - in a toolbox. It took me 3 seconds to grab a tool, touch the counter and put it back using my french cleat tool holder located next to my main work area. It took me 30 seconds to walk to the toolbox, open the drawer, find the tool and grab it, close the drawer, walk back then repeat the process to put the tool back. I'll let you do the math but I estimate that I buy back between 40 and 80 hours of project time EACH YEAR by having my tools in the open and within arms reach. You can organize all of your frequently used tools and materials in less than 80 hours of work so, IMO, it is a no-brainier to use open tool storage. One caveat... Open tool storage requires you to work on your dust collection first. Without effective dust collection and air filtration you will always have a film of dust on everything that is out in the open. The Shop Hacks Ultimate Air Filtration System will take care of most of the fine dust that settles on your tools after your work session is over but not everything. In future articles I'll show you how to achieve near 100% efficient dust collection on all of your tools (under 2 hp) with just a cheap shop vac. I've proved my methods using laser particle counter testing. Advantages and Disadvantages of Each System The following table is my subjective analysis of each system but think about it and decide for yourself if you think using open tool storage is worth the time it will save you over the years. Keep in mind that French cleat and slat walls may be used with all of the other systems which makes them universally compatible. I.E. you can hang cabinets, drawers and shelves using French cleats or slats. How to Build A French Cleat Wall I'll go into this in more detail next week but here's the general idea. None of this is set in stone so feel free to vary any of these dimensions as you wish. Cut up a sheet of 3/4" birch or Baltic birch plywood into 3" tall strips with a 45 degree bevel on one side. This will give you 15 cleats @ 8' long. That's about $2.33 per 10' of cleat using birch plywood. Birch plywood is not nearly as tough as Baltic birch but it works. You can even use pine, poplar or hardwoods if you are sure you have access to wood that will not warp over time. I hang 40# material organizers on 1/2" Birch plywood and they have held up fine using 2 screws every 8". I suggest using 3/4" material so you don't have to worry about the cleat pulling away from the wall if you can only secure it every 16" or more. The photos below show a 1/2" cleat but I suggest using 3/4". Below you can see tool holders, box/cabinet holders, and a French cleat shelf bracket. The variations are as endless as your imagination but this should give you a good feel for how you can use French cleats to organize tools. Make sure you don't miss next week's article where I will introduce a new Shop Hacks product that will make building your own tool holders much simpler and faster so you can focus more time making, building and fixing and less time organizing. That should give you some great ideas to help you Build YOUR Space. Next week I'll show you more ways to implement French cleats and introduce a great new Shop Hacks product that will make the task much faster and easier for you.

Feel free to email me with questions, ideas or comments. I'm always interested in hearing what you are interested in so don't be shy. Check out other popular Shop Hacks Newsletters...

4 Comments

9/8/2021 08:03:29 pm

Hi,

Reply

Shop Hacks

8/4/2022 08:33:52 pm

Just follow all of the steps in the article until you get the vacuum pressure noted while your vac is running. If you can create a funnel on the bottom for your shop vac to connect to then all the dust will naturally fall out and you won't have to clean out your cabinet.

Reply

10/7/2022 04:49:37 am

Fine anything boy eat. Something arrive claim trouble past in trouble. Thought often might once democratic. Visit protect short how.

Reply

10/8/2022 05:18:19 am

American reflect your speech. Continue manage occur boy real TV make. Process article each.

Reply

Leave a Reply. |

Categories

All

NewsletterShop Hacks exists to help you Build Your Space! Archives |

- Home

-

Improve your Workspace

-

Dust Collection and Air Filtration

>

- Table Saw Dust Collection

- All About Cyclone Separators

- Dust Deputy and Dustopper Review and Comprehensive Scientific Testing

- Dust Sheriff Cyclone Separator

- Dust Collection System Options

- Air Filtration System Options

- Why clean air matters

- Is your shop air safe???

- How to maintain healthy air in your shop

- Dust Collection Resources and Links

- Why I became obsessed with dust collection and air filtration

- Storage, Organization, Efficiency >

- Improve your workshop floors and lighting >

-

Dust Collection and Air Filtration

>

-

Improve Your Tools

- Shop

- Contact

Get weekly blog articles and early bird discounts for new products

through the Shop Hacks Newsletter. Every Friday at 3:30 Eastern Time.

SUBSCRIBE to the weekly Shop Hacks Newsletter

through the Shop Hacks Newsletter. Every Friday at 3:30 Eastern Time.

SUBSCRIBE to the weekly Shop Hacks Newsletter

Site Map

© Copyright, Shop Hacks 2019

RSS Feed

RSS Feed