|

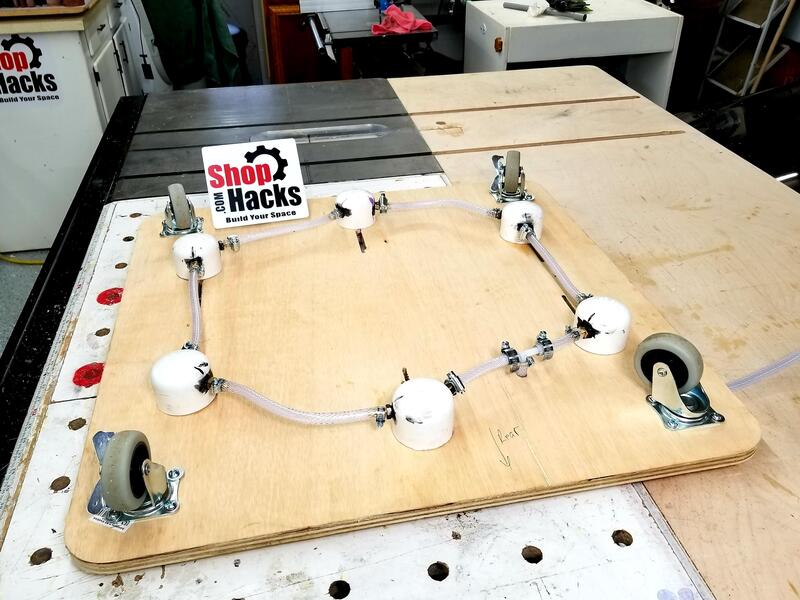

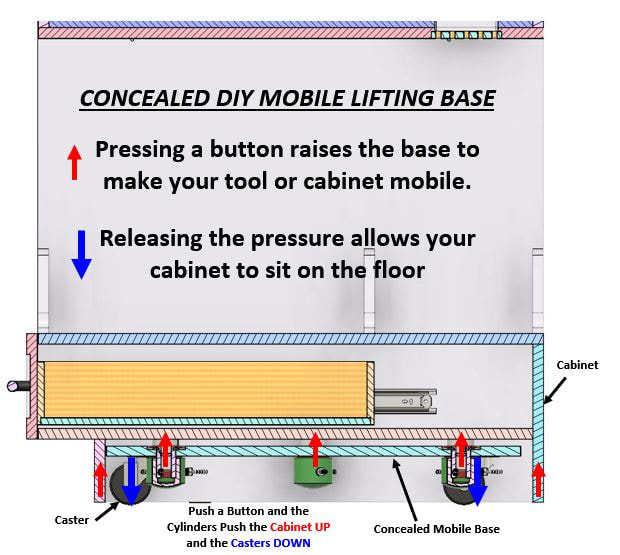

If you would like to receive the Shop Hacks Newsletter every Friday at 3:30 Eastern... just click the button... When I designed the Shop Hacks Ultimate Flip Top Workbench I wanted a way to make it mobile that didn't require any hardware to protrude beyond the base of the cabinet. I couldn't find any mobile tool bases that were concealed so I designed my own using common tools and materials and the DIY Mobile Tool Base that I'll show you how to build today was born. You may have noticed that I didn't include the adjective "ultimate" in the name of this product. While it works wonderfully and I couldn't be more pleased with it, I see this as more as a idea generator for applications for the cylinder concept used here. There probably won't be that many people who want to build this exact mobile base. However, this cylinder design can be adapted to have anywhere up to 15 feet of stroke if you like. I have made versions of this to lift close to 200 lbs over 3 feet with a residential water supply and a hose. Think outside of the box and consider what you might be able to do with such a low cost DIY hydraulic cylinder design. If you come up with some ideas then post them in the Shop Hacks Facebook group with the rest of us. I can't wait to see what might come out of this. The concept and implementation are fairly simple. I built 6 hydraulic cylinders out of PVC pipe, filled them with water and used a simple 12VDC air pump to pressurize the cylinders that lift the cabinet off the floor. When the cabinet lifts the casters are pushed against the floor which makes it mobile. When the pressure is released the cylinders retract and the cabinet rests firmly on the floor like it would if it didn't have a mobile base. You can see how it works in the short videos HERE. You can see more details about how the system works in the following photos and illustrations... With a little trial and error you will be able to build this system from the information in this article. If you are interested in saving some time by having detailed instructions, more illustrations and detailed drawings for each component you can purchase the plans HERE for the discounted price of $5.95 published only to Shop Hacks Newsletter subscribers until 9/10/19. The plans include 27 pages of photos and dimensioned drawings as well as a complete hyperlinked parts list to you don't have to search for parts. Shop Hacks is solely supported through the sales of plans and affiliate links so thank you for considering a purchase to support more free content like this to help Build YOUR Space! Affiliate links take you to the sales pages for products mentioned in this article. They are listed at the exact same price as you would see if you search on your own but Shop Hacks receives a small commission from anything you purchase within 24 hours of clicking on an affiliate link. Its a free and easy way to support more content. If you are interested in plans for the Ultimate Flip Top Workbench (pictured below) that inspired this build, just click on the link to find out more. Tools required: You won't need any special tools or materials to build the DIY Mobile Tool Base with DIY Hydraulic Lifts. Here's a list of tools that you will need...

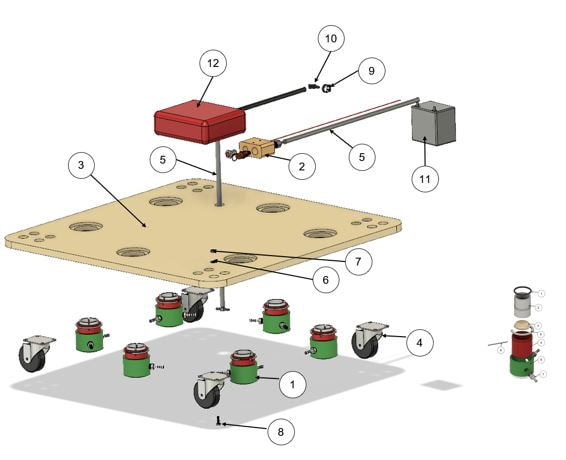

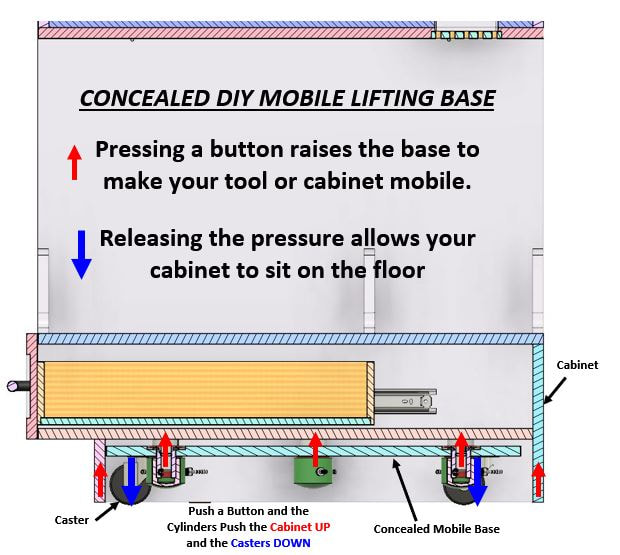

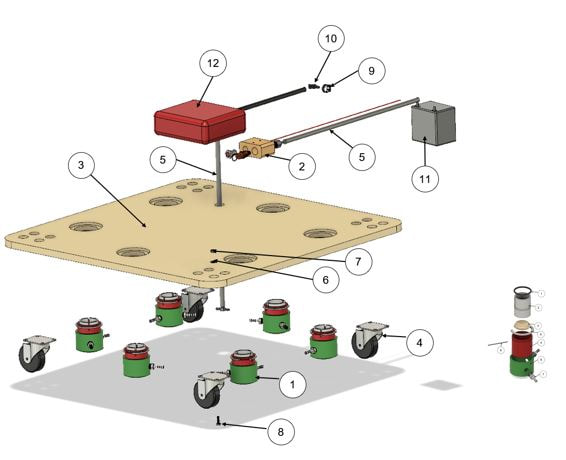

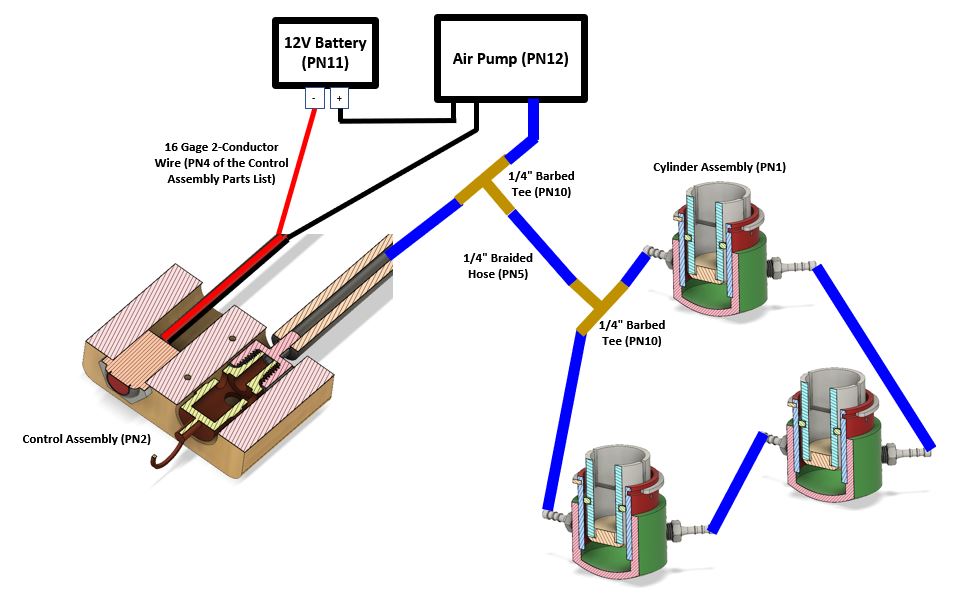

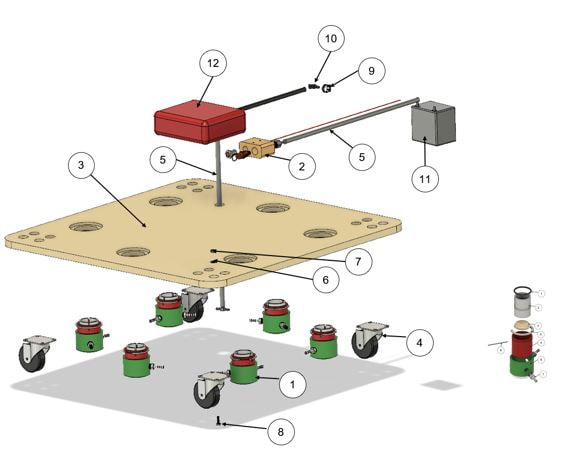

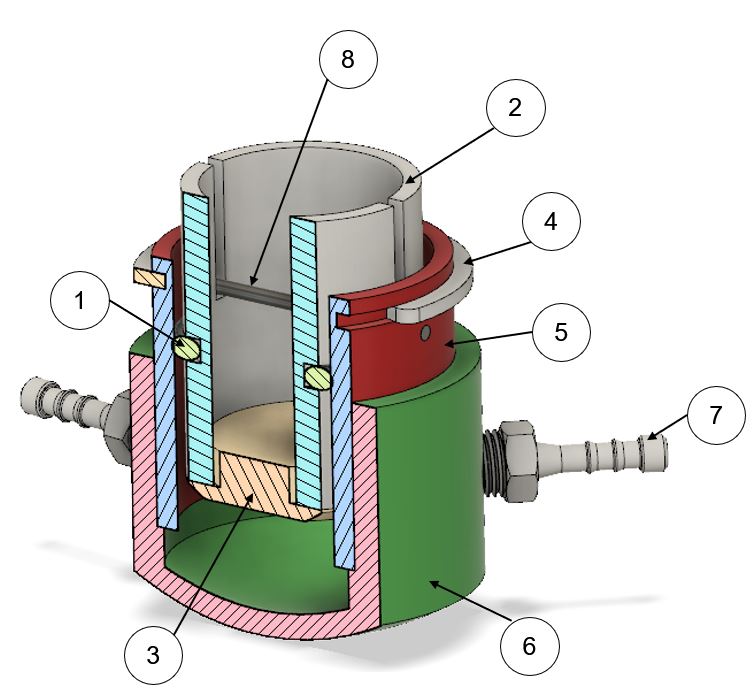

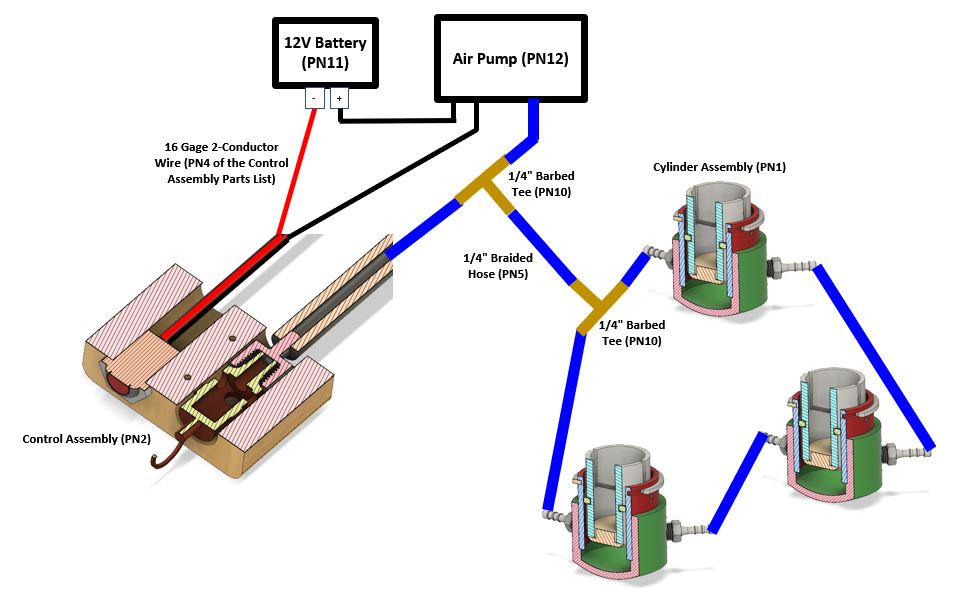

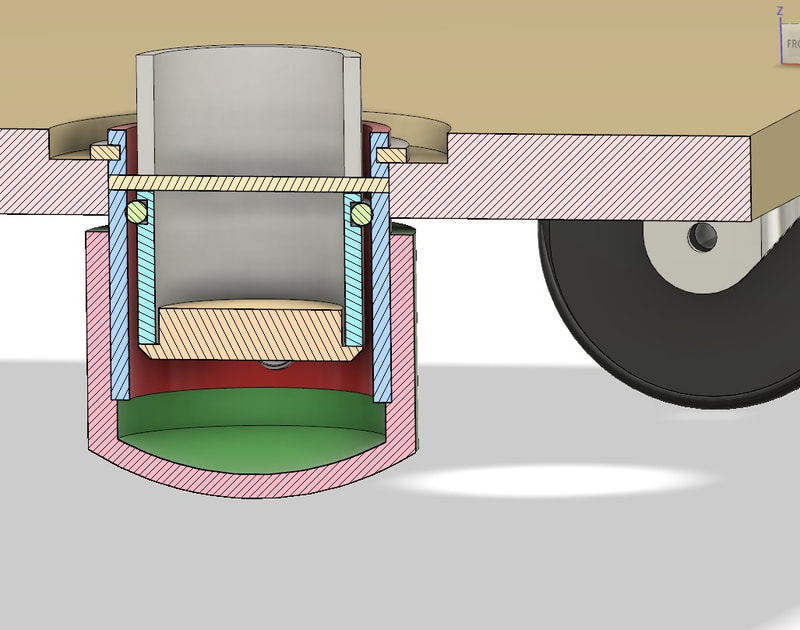

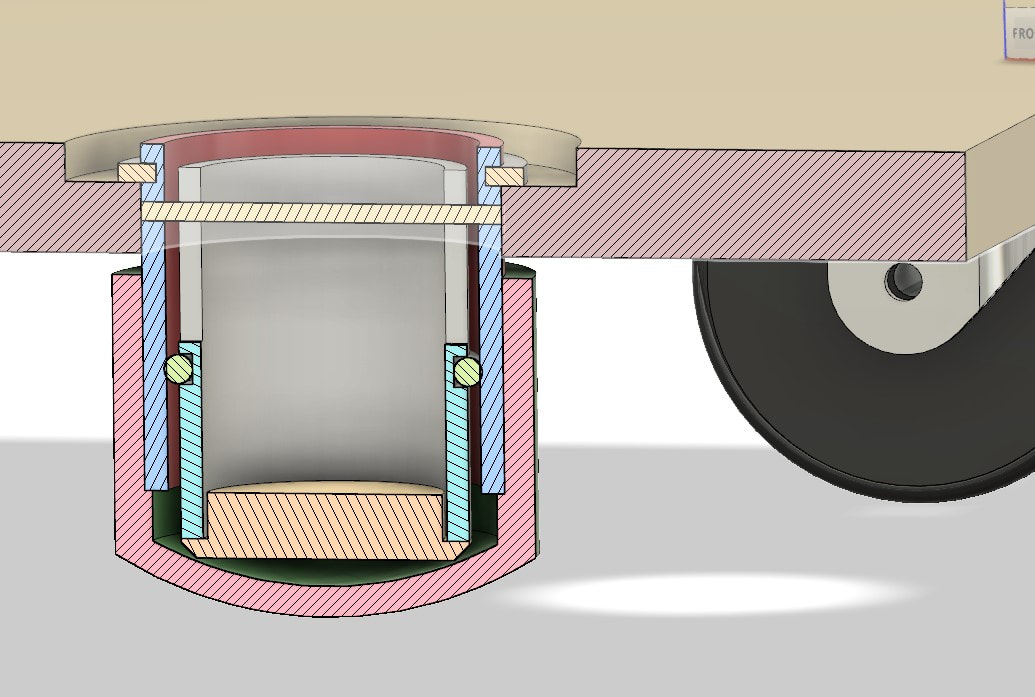

The illustration below shows you an overview of the top assembly at a glance. All of the numbered parts have associated drawings or purchase links in the plans. The illustration below shows you the detailed components of the Hydraulic cylinders. Again, the detailed dimensioned drawings and part links are included in the plans. The hydraulic cylinder is made from Schedule 40 PVC pipe, a wooden or plastic plug epoxied into the bottom of part number 2, a plastic retaining ring, an O-ring, a steel retainer rod and a couple barbed fittings. The grooves can be cut using a table saw or router table setup. I outline a method to safely and accurately cut the grooves in the plans. You need to drill and tap the NPT holes for the barbed fittings. I made the mistake of just drilling them and trying to tap them with the fittings themselves and it cost me a lot of wasted time trying to fix leaks. WARNING: Do NOT pressurize PVC pipe with air only. Even though this assembly can probably handle much more pressure than the pump can deliver, there is a chance in just the right set of circumstances that it could crack and shatter causing it to send sharp pieces of plastic flying. So, this system is meant to be an "air over liquid" system. All of the cylinders are filled with oil or water and the air pump pressurizes a relatively small volume of air. I used water in mine because my shop never goes below freezing. If your shop goes below freezing then you should add antifreeze or use oil instead of water. The following illustrations show how the system works overall. When you press the momentary switch it turns on a 12VDC air pump that pressurizes the cylinders and they extend. When the cylinders extend they press against the bottom of the cabinet, or against the frame supporting your tool, which forces the casters down and lifts the tool. You can move the tool on the casters. When you want it to be planted firmly you just pull the pressure relief valve which releases the air and forces the cylinders to retract under the weight of the tool. I'll show the cylinders extended and retracted to make it clearer. So, there you have it... a DIY mobile tool base with DIY hydraulic lifts that you can make in your own workshop. Like I mentioned earlier, the plans include 27 pages of detailed instructions, photos and illustrations if you want to save some time.

I may consider selling hardware kits that include the items you might not have readily available. If you are interested in seeing a hardware kit made available for this system just let me know in the comments or in the Shop Hacks Facebook Group. I"ll include a few links to some of the parts I recommend for this build to get you started... Set of 4 @ 3" Casters with a 300 lb each load rating. Sealed lead acid 12V battery 12VDC Air Pump 5A Momentary Switch Don't forget that you can modify this design to have as much stroke as you want and use it for other purposes. I'm looking forward to seeing what some of you will come up with!

3 Comments

JD Parker

9/9/2020 07:35:12 pm

hi! Can you give an estimated materials cost for this lift? It looks really cool, and I was thinking of adapting it for a scroll saw. Thanks!

Reply

2/17/2021 04:58:49 pm

45 years ago I made a garbage compactor using 40 psi water pressure to develop 1200# pressure( 40# psi x ~30 sq inch (6" dia poly concrete test cylinder). The poly cylinder was reinforced with glass fiber packing tape. Stroke was about 9" usable.

Reply

Leave a Reply. |

Categories

All

NewsletterShop Hacks exists to help you Build Your Space! Archives |

- Home

-

Improve your Workspace

-

Dust Collection and Air Filtration

>

- Table Saw Dust Collection

- All About Cyclone Separators

- Dust Deputy and Dustopper Review and Comprehensive Scientific Testing

- Dust Sheriff Cyclone Separator

- Dust Collection System Options

- Air Filtration System Options

- Why clean air matters

- Is your shop air safe???

- How to maintain healthy air in your shop

- Dust Collection Resources and Links

- Why I became obsessed with dust collection and air filtration

- Storage, Organization, Efficiency >

- Improve your workshop floors and lighting >

-

Dust Collection and Air Filtration

>

-

Improve Your Tools

- Shop

- Contact

Get weekly blog articles and early bird discounts for new products

through the Shop Hacks Newsletter. Every Friday at 3:30 Eastern Time.

SUBSCRIBE to the weekly Shop Hacks Newsletter

through the Shop Hacks Newsletter. Every Friday at 3:30 Eastern Time.

SUBSCRIBE to the weekly Shop Hacks Newsletter

Site Map

© Copyright, Shop Hacks 2019

RSS Feed

RSS Feed